When You Choose a Cat Gas Compression Engine, You’re Investing in The Best Equipment for Your Business.

From service and monitoring to rebuilds and overhauls, there are a range of options when it comes to maximizing that investment. When your engine is starting to show signs of wear and tear, a rebuild is often a better solution than replacing it with a new unit. Count on Cleveland Brothers Engine Rebuild Center to extend the life of your engine and bring back the longevity, reliability and peak performance Caterpillar G3500 and G3600 gas compression engines are known for.

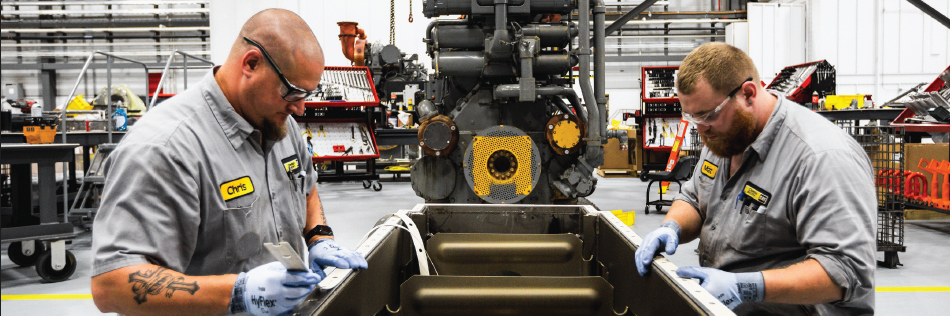

When it comes to engine rebuilds, your partner choice is critical. Cleveland Brothers Cat Certified technicians and dedicated state-of-the-art 165,000 sq. ft. facility bring thousands of hours of expertise to every Cat gas compression engine rebuild. Our rebuilds and overhauls deliver the precision, expertise and best practices you can rely on to restore your Cat engine to its original specifications. These rebuilds extend engine life cycle and deliver day-one performance and specs for more years of reliable performance.

In this comprehensive guide, we’ll walk you through the essentials of a Cat engine rebuild, providing the tips, insights and best practices you need to make the right decision for your business and ensure a successful rebuild process. Whether you’re a seasoned professional or new to the world of engine maintenance, this guide is your roadmap to confidently choose the best partner for your engine rebuild.

The Engine Rebuild Process: An Overview

Before we dive into the specifics, let’s start understanding the Cat engine rebuild. It’s a comprehensive process that involves complete engine disassembly – down to the last bolt – inspecting all components, refurbishing or replacing worn parts and reassembling the engine to like-new condition – while testing the results and documenting every step of the way. The goal is to restore performance, efficiency, and reliability while minimizing downtime and maximizing the engine’s lifespan.

Key Phases of a Cat Engine Rebuild:

1. Engine Disassembly

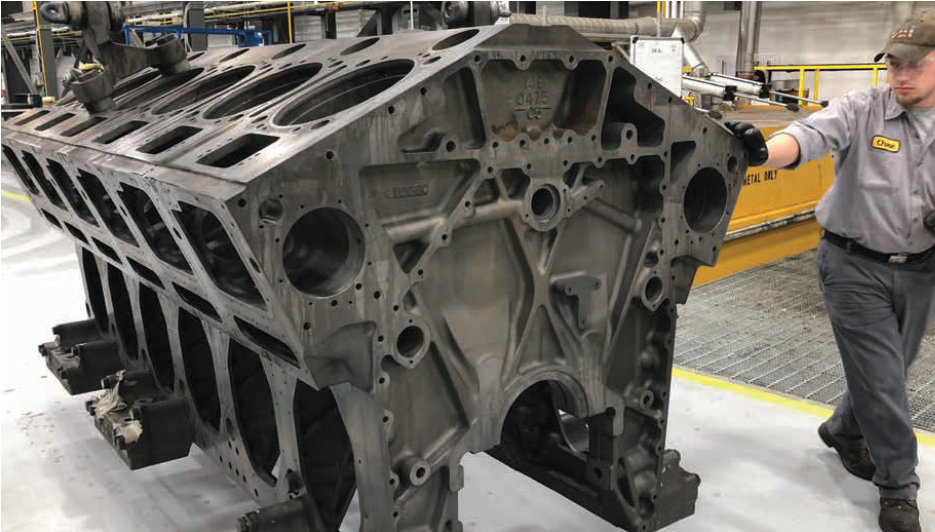

The engine is carefully disassembled down to the bare block, ensuring every component is inspected and evaluated.

2. Engine & Component Decontamination

Our dedicated facility allows for decontamination in a controlled environment while specialized cleaning agents and processes are used to remove all dirt, oil, and contaminants. This includes tools for disassembly, cleaning, and reassembly.

3. Component Inspection

Every component, from pistons and rings to bearings and seals, undergoes a rigorous inspection to assess its condition and determine whether it can be reused, restored or needs replacement.

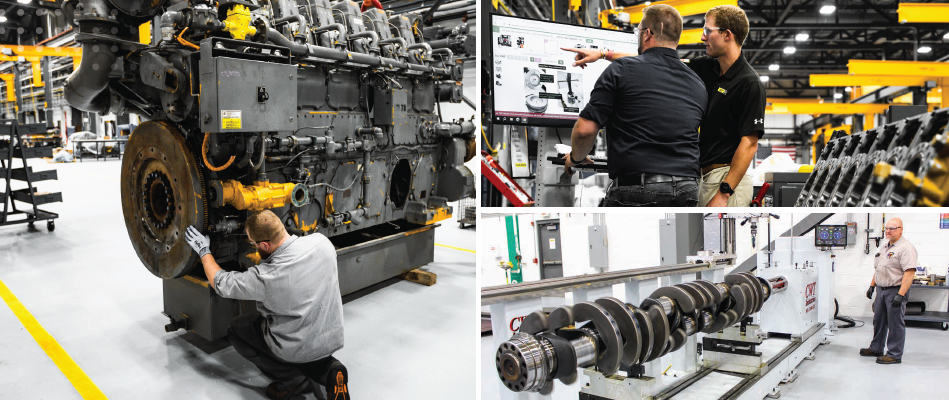

4. Precision Machining

Critical components may require precision machining to restore them to Caterpillar OEM specifications. This can include cylinder bore machining, crankshaft grinding, and other parts that are worn or performing below spec.

5. Component Replacement

Worn or damaged components are replaced with genuine Caterpillar parts to ensure quality and compatibility.

6. Assembly and Testing

The engine is reassembled with the utmost attention to detail, including torque specifications and precision assembly techniques. Postrebuild, rigorous testing, including dyno testing, is performed to verify performance.

7. Quality Assurance

Comprehensive quality control processes are followed to ensure the engine meets or exceeds Caterpillar’s OEM standards.

Now that we have a good understanding of all the things that go into a Cat engine rebuild, let’s dive into best practices and tips to ensure its success.

Best Practices for a Successful Cat Engine Rebuild

1. Choose the Right Rebuild Center

The first and most critical step in a Cat engine rebuild is selecting a reputable rebuild center. Cleveland Brothers Engine Rebuild center understands how your business needs the highest standard of quality, reliability and performance. When it comes to your work, you don’t cut corners – we don’t either. Our Engine Rebuild Center has successfully performed over 200 complete engine rebuilds. And we believe our track record speaks for itself. Our certified technicians, extensive experience and access to Caterpillar OEM guidelines set us apart. Cleveland Brothers’ Engine Rebuild Center, the largest east of the Mississippi, is a prime example of a facility with the expertise and capabilities you can rely on for a top-tier rebuild.

2. Prioritize Safety

Safety should be a paramount concern during the rebuild process. We follow all recommended safety protocols and provide training to personnel involved in the rebuild. Our Engine Rebuild Center prioritizes safety in every aspect of our operations.

3. Start With a Comprehensive Inspection

A thorough inspection is the foundation of a successful rebuild. Every component, no matter how small, should be meticulously inspected. Non-destructive testing (NDT) techniques can reveal hidden flaws that might otherwise go unnoticed.

4. Use Genuine Caterpillar Parts

When replacing components, always opt for genuine Caterpillar parts. These parts are designed to Caterpillar’s exact specifications, ensuring compatibility and performance. Counterfeit or substandard parts can lead to problems down the road, forcing you to miss targets with unexpected downtime that forces your operation to a halt and leaves you scrambling for a solution.

5. Precision Machining Matters

Precision machining is often necessary to restore components like cylinder bores and crankshafts to their original specifications. We guarantee machining is performed with the highest precision and accuracy – when 1/32nd of an inch can mean the difference between optimal performance or disaster, close enough isn’t good enough.

6. Follow OEM Guidelines

Adhere to OEM guidelines and specifications throughout the rebuild process. These guidelines are the gold standard for Caterpillar engines and are essential for achieving the best results.

7. Attention to Detail

Cleveland Brothers pays meticulous attention to detail during assembly. We follow torque specifications, use the correct tools, and employ precision techniques to avoid issues like leaks, excessive wear, or misalignments.

8. Thorough Testing

After reassembly, the engine should undergo thorough testing, including dynamometer (dyno) testing, to verify performance, identify any issues, and make necessary adjustments. Testing ensures that the rebuilt engine operates as expected. Our facility houses two dyno test cells capable of testing services up to 8,000 HP.

9. Quality Control

Cleveland Brothers implements the highest level of comprehensive quality control processes to catch any discrepancies or issues before your engine is put into service. We pride ourselves on quality assurance that delivers critical long-term reliability for your business.

10. Regular Maintenance

Once your engine is back in operation, we work with you to plan and prioritize regular maintenance schedules, ensuring continued performance and longevity. Following Caterpillar-recommended maintenance schedules and correcting small issues saves you from major breakdowns that worsen and wear over time.

Conclusion

A Cat gas compression engine rebuild is a complex process that demands precision, expertise and adherence to best practices. Choosing the right rebuild center, prioritizing safety, following Caterpillar guidelines, and focusing on attention to detail are crucial in ensuring a successful rebuild that restores your engine to like-new condition.

Cleveland Brothers is a family-owned business offering three generations of expertise, service and support to our customers and the community. When you partner with us, it’s personal. For over 75 years we’ve proudly served the region with unparalleled service, experience and support. Our new state-of-the-art Engine Rebuild Center expands our capabilities for engine rebuilds, offering unrivaled quality, expertise and facilities dedicated to getting the job done right. Partner with us to navigate your next Cat engine rebuild with confidence.

Our 24/7 parts hotline, dedicated technicians and Caterpillar Certified engineers are only a click or a call away.

Still not sure which choice is right for you? Request more information by calling 1-800-538-1020 or visit our website

Share This: