By Geoffrey Cann

It Happens To Everyone at Some Point

After five years at our current home, we decided this year it was time to renovate. The pandemic brought it to a fore when we ran out of working space, forced on us from work from home policies. We quickly grew frustrated with the work arounds, the inefficiencies, and the costs. After a false start, we got going in ernest with an extensive modernization—windows, doors, floors, cabinets, baths, kitchen, appliances, heating, and plumbing. It’s been a touch stressful but on the whole very gratifying to see it finally come together (move in day is December 20!).

Enterprise resource planning (ERP) technology, or indeed any embracing software product to automate some important chunk of the business, is the home where your business lives from an information point of view. Like my home project, you eventually reach that awkward point where the work-arounds, hacks, compromises, and allowances you make for technology simply pile up too high and it’s time for an overhaul.

There are exceptions, of course. A vintage 1990s SCADA system monitoring hundreds of oil wells in a production field might never be overhauled as the cost to take the wells out of service for the overhaul for no increase in production craters the economics. If you try to sell such outlandish ideas as SCADA system changes to oil and gas companies you might keep that in mind.

For big energy companies, however, the time for some kind of major overhaul is probably very soon, driven by two key factors.

Energy Transition Pressures

The mix of energy products both supplied and consumed is undergoing very dramatic change. Oil demand peaked in the OECD a decade ago, and China now projects that fuel demand (the biggest slice of the barrel) has crested this year as electric vehicle sales now outpace gasoline vehicles. Liquefied natural gas (LNG) demand shifted overnight to Europe because of the war in Ukraine. The Inflation Reduction Act has unlocked billions of dollars in investment in the US for new energy products (hydrogen, carbon capture and storage, geothermal, power, energy storage, solar farms). Governments are throwing incentives at businesses everywhere to replace their fossil fuel demand (heat, transportation) with cleaner energy. Many homeowners like me are upgrading windows, improving insulation, adding heat pumps, and installing solar panels.

The pace and direction of change is messy and uneven. For example, replacing all one billion running cars with battery electric will take at least two decades because we can only make so many cars each year.

New network assets like power grids require extensive permitting, which has slowed dramatically in the past five years. Oil refineries are lumpy and cannot gradually reduce the amount of gasoline output without impacts to equipment and economics. Shortages of new oil tankers are already programmed as shipowners have curtailed new builds starting last year.

Suffice to say, enterprise solutions that date back to the turn of the century, a time of relative stability, low growth, and limited change, are not set up for success in this more kinetic and uncertain environment.

Digital Transformation Pressures

Digital change exerts its own pressures now. New technologies, like cloud computing, mobility apps, robots, ChatGPT and its brethren, offer all kinds of new capabilities that are within reach of any company. Sixty percent of oil companies started leveraging cloud computing just since 2021, driven by the COVID 19 pandemic and safety protocols like social distancing, travel restrictions, and work from home arrangements.

These technologies also unlock new business models that have the potential to transform how business works. For example, using an AI platform as a natural language database for holding engineering content lets an oil company save as much as 80% of total engineering time that is lost to searching for old content. Putting a consumer grade iPhone into an intrinsically safe case lowers the cost of front line access to data dramatically.

And consumers have grown to expect that their relationship with a brand will be both defined by, as well as largely enabled through, technology such as apps, AI assisted support, and augmented reality.

The Case For Change

Modernization of ERP systems is a thing. At a recent SAP conference I attended, an integrated super-major set out the case for making dramatic changes to their ERP landscape, triggered overwhelmingly by the twin forces of energy transition and digital transformation.

The Status Quo

For this super-major, but likely almost all oil companies, as the vast majority have not bothered to migrate their ERP to the new digital architecture, the case for the overhaul boiled down to the following factors:

- The ERP systems (as there were multiple incompatible instances) had become costly to maintain, as they had been customized over the years, and the custom additions required additional dedicated resources to keep them running smoothly.

- There were no trusted data models and no existing standards for data, which forced extra time and cost to design, model, test and implement process changes.

- With data siloed around the business, there was no single source of truth, resulting in a persistent distrust of any metric, analysis, report, insight or conclusion.

- Employees implemented manual hacks and workarounds to solve for these challenges, many of which were undocumented, unreliable, and accretive to the trust problem.

- Processes were consequently error prone, driving an avoidable investment in high cost fact checkers, reviewers, troubleshooters, disruptive expedited resolutions, and restatements.

- The overall landscape of processes, systems and data was rigid and inflexible, creating a kind of gridlock. Proactive response to both required changes (tax, carbon management, ESG) and market opportunity were severely hampered.

- New technologies, like augmented reality, mobile apps to the front line, were out of the question, because the underlying data was simply not reliable.

- There was a proliferation of incremental point solutions that were lightly managed (ie, under resourced or not budgeted for) whose role had moved from ‘interim fix’ to ‘mission critical’.

- Inorganic growth had resulted in too many additional complex architectures and solutions added to the mix, all of which had continued past the acquistion date.

It was clear to the super-major that its systems were rapidly closing in on end of life and that a significant technical debt was now due.

The Target

Jumping into an overhaul of such a complex and costly landscape requires a thoughtful plan. The super-major set out a series of broad directional goals that they wanted to achieve, and the contours of their target future environment. These included:

- A digital backbone, which would allow access to newer technologies, including SAP 4/HANA, SAP’s flagship ERP platform for the digital age.

- Cloud services, which would unlock the new business models as well as SAP’s platform.

- Technology advances such as app stores, third party solutions, machine learning, and trust ledgers, intended to increase the nimbleness of the overall architecture.

- Standard business processes, including those from industry partners in such areas as revenue accounting and field service, eliminating the customizations, hacks, and work arounds, resulting in a dramatically simpler technology landscape.

- Overall business simplification, which would lower cost and help pay for the overhaul.

- Most importantly, a common data model, which would be central to the business processes and simplification agenda.

Paying for It

Nothing happens in oil and gas unless the cash register rings, and that includes the overhaul. On principle alone, oil and gas executives will not sanction anything that involves a spend of money unless it generates a return. Four easy places where overhauls can pay for themselves include supply chain contract management, contract leakage, services management, and inventory control. ERP solutions are supremo in this areas.

The ’Do Not’ Lessons In Instance Management

Very large organizations will often have multiple instances of a specific technology solution like SAP, configured differently to meet different business needs. For example, the needs of a commercial unit that delivers fuel products to other wholesalers as well as to a captive chain of retail outlets has quite different needs than a refinery which is principally a manufacturing business.

In the case of this particular super-major, its global corporate footprint consisted of some 700 different business units, varying in scale from tiny to gargantuan, with an equally broad set of business needs, operating languages, and currencies.

Some of their ‘do not’ lessons from their overhaul approach apply equally to many other similar businesses:

- Do not blindly deploy enterprise solutions following the corporate entity structure. There is an industrial logic to tying technology to specific balance sheets, but the likelihood of inconsistent data, incompatible processes, and lost scale economies makes this a costly strategy.

- Do not insist on a single instance strategy for the whole of company. Single instance is the siren call of IT who have to support technology, but a single configuration will not fit complex businesses that are operating in more than one line of trade.

- Do not overwhelm small business units with large business solutions. The ERP solution that works for the world’s largest retail chain is not fit to serve the needs of the 40-person hydrogen manufacturing pilot. Nothing hurts the chances of a small nimble business more than saddling it with the rigour and stately processes of a gigantic oil company.

- Do not customize. Nothing cements in higher cost, lower data quality, and an inability to embrace change than customized code. The ideal model is to embrace the market standard unless there is a thoroughly compelling reason to do otherwise. A clean core is far more sustainable at a lower total cost of ownership.

The One Must Do

There are lots of ‘do nots’ in the world, but is there a MUST DO? As I set out in my books, overhauls of this scale do not happen without robust change management. The super-major shared plenty of insights on change management, but the one MUST DO that stood out for me was to make data the sexy thing.

As they pointed out, data in oil and gas is not a sexy thing. The sexy things in oil and gas are the tangible assets—rock, steel, cement, and anything energized. It’s difficult to get inspired by data when the alternative is a muscular top drive drill rig.

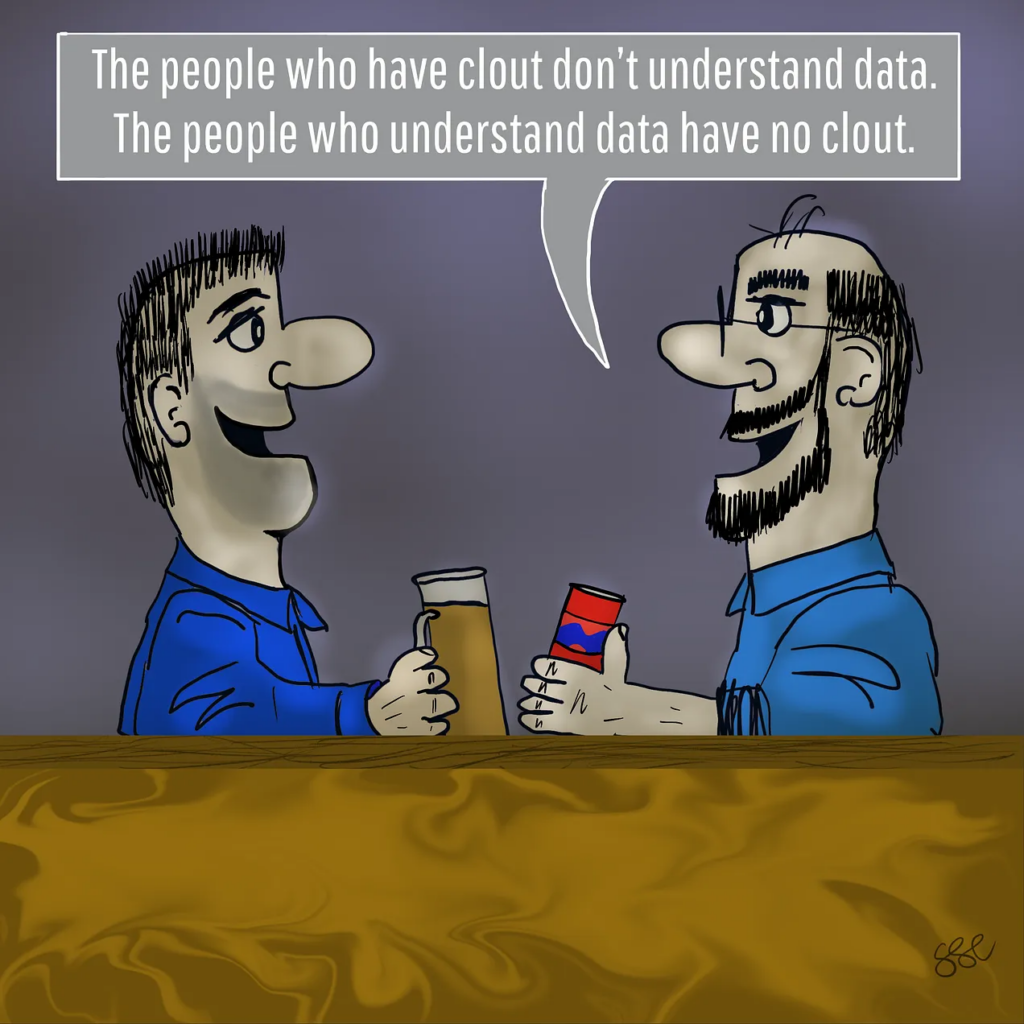

Unfortunately, the people who understand data do not have the clout to make data sexy, and the people with the clout do not understand data at all.

If you’re in charge, when you embark on the extensive renovations required for your enterprise solutions, your one MUST DO is to place data at the front, and everything else will fall into place.

Artwork is by Geoffrey Cann, and cranked out on an iPad using Procreate.

Share This: