Cleaner monitoring and maintenance are at the core of conveyor safety. If a belt is not sufficiently cleaned, fugitive dust and material can get into machinery and rolling components raising the potential for fires.

Clearing of carryback from inadequate belt cleaning can increase the chances of workers making incidental contact with a moving belt, one of the main causes of conveyor belt injuries according to WorkSafe Australia.

The need for conveyor belt cleaning is well established. Excessive fugitive material can reduce component and belt life by as much as 30 per cent, while a multiple belt cleaner system contributes less than five per cent to overall belt wear, delivering a significant benefit.

For operators who have “tried them all” and can’t find a cleaner that works, it could be that the problem isn’t the equipment, but the maintenance.

It may sound elementary but there is a great deal of knowledge and skill required to tune a belt-cleaning system to work under varying material, environmental and belt cover conditions, while still operating safely, effectively and economically.

Some manufacturers provide factory-trained direct service personnel and replacement parts, delivering expert maintenance for optimum performance and component life.

The proper equipment

The number and style of belt cleaners depend upon balancing many factors. First, the level of cleaning. Applications like coal mining or power generation cannot tolerate much carryback because accumulation can be fuel for a fire.

Once a level of cleaning is established, the next task is determining the type and number of cleaners required to do the job.

The trend in belt cleaning, regardless of application, is to plan for two or more cleaners per discharge (primary, secondary and tertiary). In addition to better cleaning from multiple cleaners, there is a redundancy factor that can provide a longer service interval window.

Then the tensioner and the best blade for the application are selected.

Safety

A trained belt cleaner service technician is aware of hazards involved with maintaining belt cleaners. Having a trained provider that focuses on safety but at the same time is more productive than in-house maintenance can be a significant benefit.

Keeping the shutdown to a minimum is important in meeting process availability goals. There are specialised systems for servicing belt cleaners where the belt runs 24–7 and can’t be shut down, but virtually all other cleaner maintenance must be performed following lockout, tagout, blockout and testout (LO/TO/BO/TO) procedures.

One primary cleaner design requires no tensioning and virtually no maintenance after initial installation. It features a matrix of tungsten carbide scrapers installed diagonally to form a three-dimensional curve around the head pulley and typically delivers up to four times more service life than urethane cleaners.

Expert service

The US Bureau of Mines and several researchers since have established that there are sweet zones for cleaning pressures for different styles of belt cleaners.

Outside of these ranges the cleaning performance is lower, while the blade wear, belt wear and power consumption are higher.

Reputable manufacturers design their cleaners and tensioners to achieve optimum cleaning performance vs. blade wear. It may seem counter-intuitive, but if the cleaner isn’t doing a good job, more cleaning pressure can actually make the problem worse.

Maintenance personnel must understand these phenomena and know-how and when to adjust each style of cleaner. Some sophisticated users optimise their cleaning performance vs. blade replacement costs by testing different blade materials at different cleaning pressures and changing blade materials and cleaning pressures for different seasons or ROM (run of mine) conditions.

Inspection and monitoring

Some manufacturers offer conveyor inspections and cleaner maintenance as part of a managed service relationship. Their monitoring systems can track component wear and update the service technician and/or operations personnel via Wi-Fi or cell phone on upcoming service needs.

There are some new systems that can even adjust belt cleaner tension automatically. The technology will also send an alert through a mobile app in the event of upset conditions.

Factory-trained service technicians provide an added set of eyes on the conveyors, travelling to and from the equipment to be serviced and logging details in their service reports. Because they see so many different applications, they can often alert on problems that maintenance personnel don’t see or have become accustomed to ignoring.

With factory-direct managed service, the responsibility for maintenance falls on the manufacturer, allowing the staff to focus on other priorities.

Return on investment

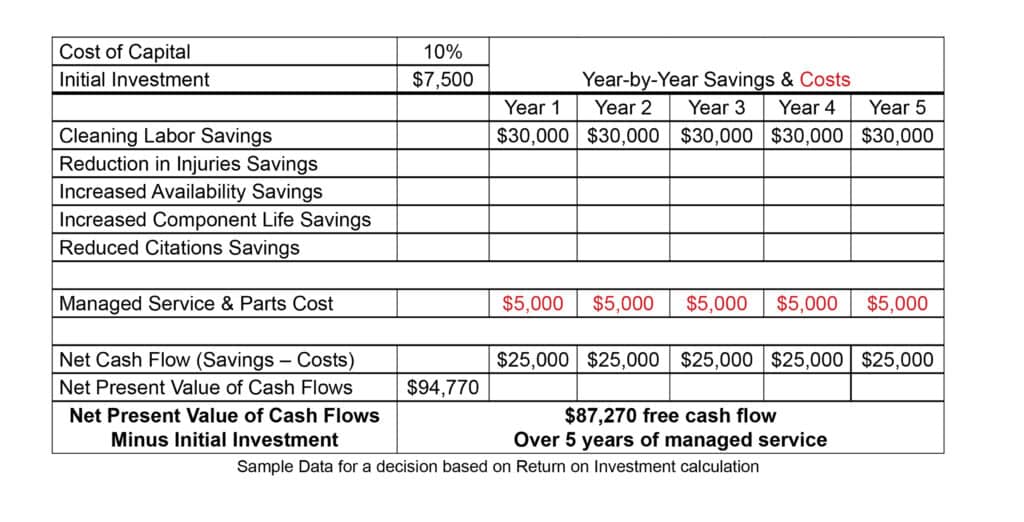

When calculating the return on investment for professionally installing and maintaining belt cleaners, the analysis should be done over the life of the belt cleaner assembly using a net present value calculation.

The following example is based on simply reducing clean-up labor by 2000 hours per year at $15 per hour.

Other benefits should also be factored in, such as the savings from avoiding injury, increased equipment availability, improved equipment life or reductions in citations and fines. Facility managers often find that cash flow values are surprisingly large over the life of the equipment and service relationship.

Belt cleaner maintenance can be time-consuming and pull labor from other essential tasks, so it’s important to choose a supplier with trained and experienced service technicians who know the equipment and safety procedures and can respond quickly to customer needs.

The automated monitoring of equipment mitigates some of the issues with blade wear and provides data and alerts when blades need servicing. This can help lower labor costs and improve safety due to fewer inspections and proactive maintenance.

Considering a managed service program can make safety and productivity sense and improve profitability with additional positive cash flow.

This article was prepared by Martin Engineering director of conveyor products, Chris Schmelzer, and Martin Engineering president emeritus, R. Todd Swinderman.