Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Hot on the heels of his record-breaking purchase of electric mining equipment from Liebherr, Twiggy Forrest has now ordered AUD$400 million of emissions-free heavy mining equipment from China’s Xuzhou Construction Machinery Group Co., Ltd (XCMG) to decarbonise Fortescue’s mining. These extra 100 “pieces of zero emissions Heavy Mobile Equipment” will be put into service in West Australia’s Pilbara mining operations starting in 2026 through to 2030. Forrest is serious about his “real zero” ambitions.

On its website, Fortescue describes itself as “the technology, energy and metals group accelerating commercial decarbonisation of industry, rapidly, profitably and globally.” It appears that batteries have won the day. It’s not that long ago that “experts” were saying this could not be done with battery electric drivetrains, it had to be green hydrogen.

Dr Forrest has made significant investments in green hydrogen research and possible deployment as well. Recently, Fortescue deployed a hydrogen-powered haul truck prototype, dubbed “Europa,” from Perth to the Pilbara where it is to complete site-based testing. “Over the coming months, the Liebherr T 264 haul truck will be tested in a real-life mining environment at Christmas Creek.” This will help inform the company’s future fleet of zero emission haul trucks. Once commissioned on site, Europa will be refuelled with liquid hydrogen from a gaseous and liquid hydrogen plant, located at Fortescue’s Green Energy Hub at Christmas Creek. Fortescue Metals Chief Executive Officer Dino Otranto said: “It’s fantastic to have our hydrogen-powered haul truck prototype now joining its battery electric equivalent, Roadrunner, up at site. Europa integrates for the first time a Fortescue Zero battery into a Liebherr haul truck, marking a huge milestone in our partnership with Liebherr.”

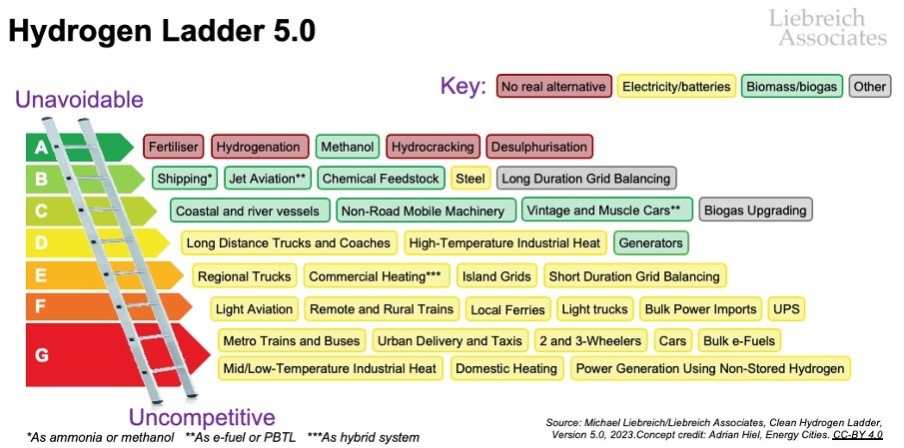

Fortescue is still trialling hydrogen to power the mining industry. It will be very interesting to see how this moves forward in the future. Fortescue operates a fleet of hydrogen cars in Perth. My money is on batteries climbing the energy ladder to outpace hydrogen.

“We’re moving rapidly to decarbonise our Pilbara iron ore operations and eliminate our Scope 1 and 2 terrestrial emissions by 2030. To achieve this target, we will need to swap out hundreds of pieces of diesel mining equipment at the end of their life with zero emissions alternatives,” stated Fortescue Metals Chief Executive Officer Dino Otranto.

“We’re thrilled to partner with XCMG to supply and support cutting-edge battery electric mining equipment, marking another significant step forward in our decarbonisation journey. As the global mining industry continues to evolve, we’re proud to be at the forefront of driving innovation in value adding green technology and showing the world that industry can decarbonise.”

Millions of litres of diesel currently being burned in Australia’s Outback will be replaced with solar energy powered machinery from China’s XCMG. By 2030, XCMG will deliver battery electric wheel loaders, wheel dozers, water carts, float prime movers and graders. The first should start arriving in 2026. It would be interesting to know the return on investment for this equipment. Dr Forrest will have done the sums, I am sure.

“XCMG is dedicated to long-termism and sustainable development, offering high-end, intelligent and green ‘product + scenario’ full life cycle solutions to global customers. The company has achieved green electrification across its entire product range, with new energy products accounting for 18 per cent of revenue, leading the industry’s green and low-carbon transformation.

“Since last year, XCMG has fully launched its ‘No. 1 Project’ for intelligent transformation, digital transformation and networking. This initiative promotes a shift from traditional, single-point and local informatisation to a global, full value chain and comprehensive business domain digital transformation. XCMG is committed to building a smart, green, and world-class company.”

“XCMG and Fortescue have formed a long-term partnership based on ‘value resonance, cultural resonance and win-win cooperation’. This collaboration will significantly contribute to global environmental protection and the development of a green, sustainable economy,” Mr Yang Dongsheng of XCMG said.

Since I had never heard of this company, I thought that might also be true of our readers, so here is a little background. XCMG is the largest the construction machinery manufacturer in China, and number 3 in the world. Its business covers 8 key areas of “construction machinery, heavy trucks, mining machinery, sanitation machinery, machinery components, construction, finance and ICT.” The company has had an 80-year history, during which it has formed joint ventures with Caterpillar and Liebherr, among others. Just like Liebherr, XCMG is moving towards “real zero” in the mining industry.

XCMG products are sold in 180 countries, with manufacturing bases in Germany and the USA. Does Donald know this? The Chinese are already in the US with quite a wide range of Blue Diamond (XCMG North America Corp) products. The company headquarters is in Las Vegas.

Of course, XCMG is quite active in China’s Belt & Road projects. One example is the Inner Mongolian mine that has purchased a batch of electric autonomous mining trucks from XCMG — the ZNK95. It is expected that the mine will reduce its diesel consumption by 47,000 tons per year as it scales up to 300 units by 2026. The ZNK95 has a capacity of 85 tons, does not have a cabin, and can operate in high altitude and extreme cold. Its drivetrain can handle steep gradients with heavy loads.

The ZNK95 can switch between short-distance remote control, long-distance remote control, and autonomous operation. I certainly hope that Twiggy Forrest has ordered a few of these.

Fortescue Metals is not owned by a woke billionaire cowboy. Dr Andrew Forrest is a mining magnate with a mission to set an example for real zero emissions. In employing battery electric mining equipment, he is not alone. Nor is XCMG the only company making such equipment. However, he is making his voice heard and perhaps it will become a rallying cry. There is a lot of mining in Australia, a lot of scope for improvement. As one of our readers pointed out: “Real zero” mining is especially important since it enables true fossil free value chains. Once the mining is “green,” then there is more chance of the final product being “green.”

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy