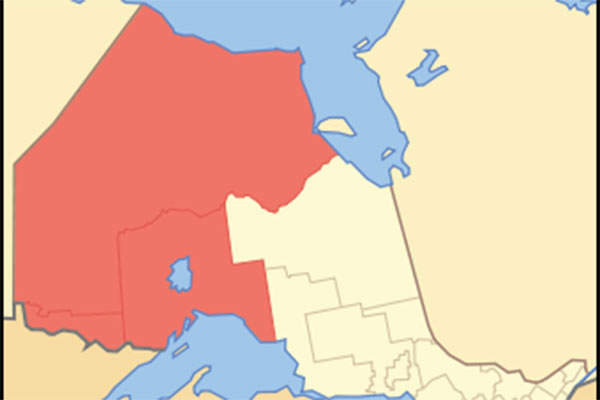

The Rainy River gold project is located in Richardson Township, approximately 65km northwest of Fort Frances in North-western Ontario, Canada.

The project is expected to produce approximately 3.41Moz of gold through a combination of open pit and underground operations. Image: courtesy of Alchemist-hp.

The processing plant will use conventional methods to produce gold-silver doré bars. Image: courtesy of Chepry.

New Gold’s fully-owned Rainy River gold project is located in Richardson Township, approximately 65km north-west of Fort Frances in North-western Ontario, Canada , one of the world’s ten biggest gold producing countries. New Gold gained control of the project by acquiring the final shares of Rainy River Resources on 15 October 2013.

The gold project will be a combined open pit underground operation consisting of a 21,000t a day (t/d) processing plant. It is expected to produce 2.81 million ounces (Moz) of gold and 5.14Moz of silver from the open pit operation, and 605,000oz of gold and 889,000oz of silver from underground operations.

The project received Federal environmental assessment approval on 12 January 2015 and provincial approval on 29 January 2015. Underground mine development is expected to start in 2017 and underground mining is expected to begin in 2019.

It is expected that the project is will have a mine life of 14 years, which includes direct processing of open pit and underground ore for first nine years and processing of a combination of stockpile and underground ore thereafter.

Rainy River gold mine geology and mineralisation

Located near Kamloops in British Columbia, Canada, the Afton-Ajax copper-gold project is being developed by New Gold and Abacus Mining and Exploration.

The Rainy River gold mine lies in the 2.7bn years-old Rainy River Greenstone Belt that forms part of the Wabigoon Subprovince, a 900km long east-west trending area of komaiitic to calc-alkaline metavolcanics that are succeeded by clastics and chemical sediments.

The deposit is primarily underlain by a series of tholeiitic mafic rocks, which are in turn structurally overlain by calc-alkalic intermediate to felsic metavolcanic rocks.

Gold mineralisation is hosted mainly by the intermediate rocks (dacites) and forms a hybrid deposit consisting of an early gold-rich volcanogenic sulphide mineralisation covered by shear-hosted mesothermal gold mineralisation.

Early gold mineralisation at the deposit hosts sulphide stringers, veins and disseminated pyrite in quartz-phyric volcaniclastic rocks, while late gold mineralisation consists of quartz-pyrite-chalcopyrite-gold veins and veinlets.

The deposit also contains nickel, copper and platinum group metals sulphide mineralisation associated with a differentiated ultramafic-mafic intrusion.

Rainy River gold mine reserves

As of 4 February 2015, the Canadian gold mine is expected to contain proven and probable reserves of 104.2 million tonnes (Mt) of ore grading 1.13g/t Au and 2.8g/t Ag. Contained gold and silver are estimated to be 3.78Moz and 9Moz, respectively.

Mining and processing of ore at Rainy River

Conventional open pit mining, including drilling and blasting, will be applied at the Rainy River deposit, based on the proximal mineralisation to the surface.

The primary fleet for open pit mining will consist of three hydraulic shovels, one wheel loader, 22 haul trucks, three Down-The-Hole (DTH) drills, and support equipment.

The underground mine will be accessed via a 4km decline from a surface portal. It will include extract 1,500t/d of ore through longitudinal longhole open stoping method. Starting from the lowest level of the zone or from an adopted sill elevation, the underground mining is expected to proceed upwards while backfilling each successive lift.

Conventional crushing, grinding, leaching, carbon-in-pulp (CIP) and gold recovery techniques will be used by the processing plant to produce gold-silver doré.

The run-of-mine material will be crushed in the gyratory crusher before being conveyed and ground in the SAG mill in a closed-circuit, which comprises a scalping screen and a pebble crusher. Undersize from the scalping screen will be mixed with the ball mill discharge and delivered to a cyclone cluster.

“It is expected that the project is will have a mine life of 14 years.”

The underflow from the cyclone cluster will feed the ball mill and a portion of the ball mill discharge will be treated by a gravity circuit. The cyclone overflow will be thickened in a pre-leach thickener and pumped to the cyanide leaching circuit, which has a retention time of approximately 30 hours.

Discharge from the leach circuit will flow by gravity to a carbon-in-pulp (CIP) circuit where the leached gold will be adsorbed onto carbon. Loaded carbon will be sent to the carbon stripping circuit where the gold and silver will be recovered as sludge in electro-winning cells, filtered, dried and smelted into doré bars.

Infrastructure facilities at Rainy River gold mine

Power for the mining operations will be supplied by a new 17km-long, 230kV power line, which will be connected to the existing 230kV Hydro One line that connects Fort Frances and Kenora.

Potable water will be obtained from the West Creek pond, while fresh water will be obtained from the water management pond and used for reagent preparation, surface utilities and for dust suppression.

Contractors involved with the Rainy River mine development

BBA prepared the technical report for the gold project with the support of SRT Consulting, AMEC, and AMC Consultants.

Caracle Creek International Consulting was engaged in 2008 to conduct mineral resource evaluations for the project.

Sign up for our daily news round-up!

Give your business an edge with our leading industry insights.