Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

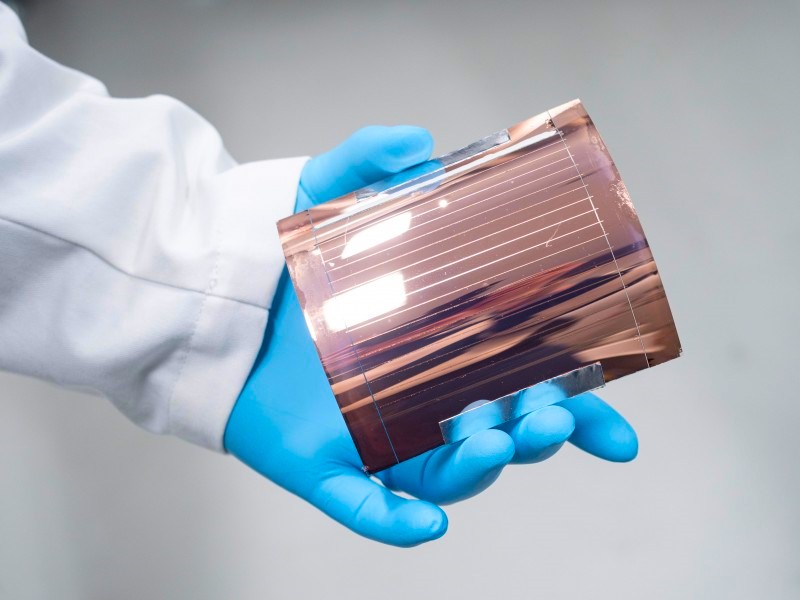

All-perovskite tandem solar cells could soon pick up where silicon solar cells reach their limits. These highly efficient, lightweight, and flexible cells have already proven themselves in the laboratory — now, Empa researchers are working on scaling them up and making them ready for the real world.

Roof tiles are becoming a thing of the past: Today, more and more Swiss roofs boast large black and blue rectangles that convert sunlight into electricity. The blueish color comes from silicon crystals, as the majority of solar cells available today are based on this semiconductor material. But silicon is not the only way to make a solar cell — and possibly not even the best.

Silicon-based photovoltaic cells have been perfected so far that they are reaching the limits of their efficiency. Although a few percentage points of improvement could still be gained, the theoretical upper limit for the efficiency of a single silicon cell is 33 percent. In practice, it is somewhat lower, as small energy losses inevitably occur during the construction and operation of the cells.

The reason for this hard efficiency limit lies in the material properties of silicon. The so-called band gap of the material means that only photons with a certain energy can be converted into electricity. If the energy of the photon is too high, it cannot be fully “utilized” by the solar cell.

Two layers are better than one

Solar cells made from other materials offer a way to overcome this limitation, says Empa researcher Fan Fu. The group leader in the Laboratory for Thin Films and Photovoltaics is researching highly efficient solar cells made of perovskite. A single perovskite cell alone does not achieve a higher efficiency, because perovskite as a semiconductor also has a limited band gap. The real strength of this innovative material lies in the fact that, unlike silicon, this band gap can be easily adjusted by varying the exact composition of the perovskite material.

If two perovskites with different band gaps are processed into thin films solar cells and “stacked” on top of each other, the result is a so-called tandem solar cell. One perovskite layer “catches” the photons with high energy, the other one those with low energy. In theory, this allows efficiencies of up to 45% — much higher than the 33% of single-junction cells. Alternatively, a perovskite layer can also be added to a silicon cell to create a highly efficient tandem cell.

However, Fu and his team are currently focusing on all-perovskite tandem cells, in particular as part of the EU research project SuPerTandem, in which a total of 15 European leading research institutions and companies are involved. The aim of the project is to develop flexible perovskite tandem modules with an efficiency of over 30 percent, which can also be produced using scalable and cost-effective processes. This is another strength of perovskite solar cells: “Silicon solar cells usually require high-purity silicon monocrystals that are produced at high temperatures,” explains Fu. “Perovskite thin films, on the other hand, can be printed, solution-processed or produced by vapor deposition with a very low CO2 footprint. Small defects that occur in the process only have a minor impact on their optoelectronic properties.”

The potential benefits of projects like SuPerTandem are significant, because the higher the efficiency, the less expensive solar power will be at the end of the day. “The cell itself only accounts for less than 20 percent of the cost of a PV system,” says Fu. “The remaining 80 percent is accounted for by the cables, the inverters, the junction box and, of course, the labor involved in installation.” If the efficiency of the individual cells is increased, a smaller — and therefore more affordable — PV system is sufficient for the same electricity output. Thin-film cells made of perovskite can also be produced on lightweight flexible films instead of heavy, rigid glass plates like silicon cells. This means they can also be used in more locations, for instance on car roofs or on buildings with a low load-bearing capacity.

From the lab to the roof

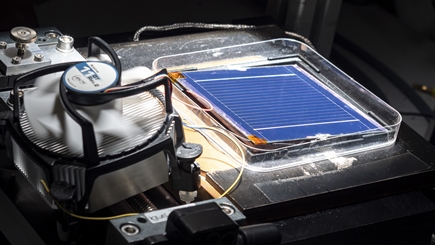

This potential of perovskite solar cells must now be exploited. In addition to SuPerTandem, Fan Fu’s team is also working on two Swiss projects. In a project funded by the Swiss National Science Foundation (SNSF), Empa researchers are working to better understand the fundamental properties and challenges of perovskite solar cells that contribute to their efficiency and stability. And in a project with the Swiss Federal Office of Energy (SFOE), they are putting their existing knowledge into practice by scaling up the tandem cells already developed at Empa.

What else do we need to do to ensure that the black and blue rectangles on our roofs are joined by reddish perovskite films? “First of all, we have to scale up the perovskite cells from the current prototypes of a few centimeters to industrial sizes,” says Fu. The cells, which are still somewhat fragile, also need to be effectively protected from the weather. Fan Fu is optimistic that both will be achieved in the next five to ten years. “We are making good progress, and there is a lot of interest from industry,” says the scientist. “Researchers have only been working on perovskite-based solar cells for just under 15 years. For comparison, research into silicon cells has been going on for almost 70 years.”

By Anna Ettlin, via Empa, Swiss Federal Laboratories for Materials Science and Technology

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Video

CleanTechnica uses affiliate links. See our policy here.