Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

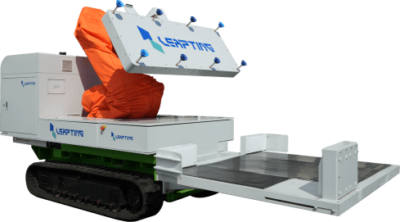

Automation is making its way into every industry, and the solar sector is no exception. Chinese automation company Leapting has just announced that its Intelligent Automatic Navigation PV Module Installation Robot will be deployed at a large-scale solar farm in Australia. The robots, which have already been shipped from Leapting’s manufacturing plant in Huzhou, are expected to dramatically speed up installation times, reduce labor costs, and improve safety on-site.

A New Era For Solar Installation

As of the end of 2023, Australia’s PV installations hit 34.7 GW. However, the increasing size and weight of PV modules, coupled with the remote locations of many construction sites, have posed significant challenges to traditional manual installation methods. These challenges include low efficiency, high safety risks, and escalating costs.

Leapting’s robot aims to tackle these challenges head-on by replacing manual labor with automation. Using high-precision visual recognition technology, the robot can accurately detect the structure and spacing of panel supports, ensuring each module is placed quickly and precisely.

How The Robot Works

The robot is designed to handle PV modules weighing up to 30 kilograms, utilizing a powerful suction cup system. It has a high-clearance chassis and crawler tracks, and features fully automated navigation, including obstacle avoidance systems. Equipped with high-precision visual recognition technology, it accurately perceives the structure and spacing of supports, which ensures the precise installation of each module.

The robot is designed to handle PV modules weighing up to 30 kilograms, utilizing a powerful suction cup system. It has a high-clearance chassis and crawler tracks, and features fully automated navigation, including obstacle avoidance systems. Equipped with high-precision visual recognition technology, it accurately perceives the structure and spacing of supports, which ensures the precise installation of each module.

Leapting reports that the robots can install 60 modules per hour — a rate of one module per minute. This automated process not only significantly increases efficiency but also reduces the safety risks associated with manual labor, leading to an estimated 30% reduction in installation costs. That’s a huge advantage for solar developers, especially in regions where labor shortages and safety concerns are major issues.

A Step Toward The Future

Leapting’s robot is set to go into operation soon at a 350 MW solar farm being built in southern New South Wales, marking a significant step forward in the automation of solar energy construction, and setting a precedent for future projects around the world.

Leapting’s robot is set to go into operation soon at a 350 MW solar farm being built in southern New South Wales, marking a significant step forward in the automation of solar energy construction, and setting a precedent for future projects around the world.

By making solar farm construction faster, safer, and more efficient, Leapting’s robot could help accelerate the global transition to renewable energy. With the industry pushing for lower costs and increased deployment of solar power, automation might just be the missing piece that makes large-scale solar even more viable. In addition to the module-mounting robot, Leapting also offers other PV-focused automated products, such as a module-cleaning robot and a module-inspection robot, which can be integrated into large solar farms to enhance efficiency and lower labor costs.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy