The Kurmuk gold project located in Ethiopia will be developed as an open-pit mine. Credit: Smileus via Shutterstock.

The Kurmuk gold project will feature two open pits, namely the Dish Mountain pit and Ashashire open pit. Credit: Allied Gold/PR Newswire.

Production is estimated to commence in Q2 2026. Credit: Aleksandrkozak via Shutterstock.

The Kurmuk gold project, located in Ethiopia, is set to be developed as an open-pit mine by Allied Gold, a mining company based in Canada.

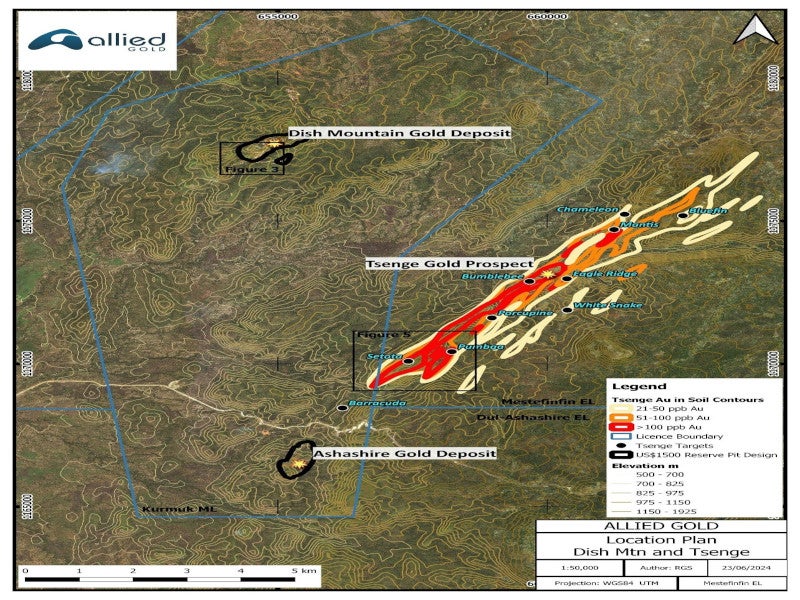

The project amalgamates two separate mining developments, namely, Dish Mountain and Ashashire. A combined feasibility study for the two pits was completed in December 2022.

The project will be developed in two phases with a total capital investment of approximately $500m for a life of mine of 15 years.

Phase one of the project is currently under construction while phase two construction is set to commence in 2025. Production is anticipated to begin in the second quarter (Q2) of 2026.

The project aims to achieve an average annual production of approximately 290,000oz of gold over the initial five years.

An average annual output of more than 240,000oz will be maintained for the remainder of the mine’s life.

Kurmuk gold project location

The property site is located in western Ethiopia, approximately 750km east-north-east of the capital, Addis Ababa. The project encompasses an area of approximately 1,561km².

Geology and mineralisation

Kurmuk is situated within the Neoproterozoic volcano-sedimentary Tulu Dimtu shear belt of the Arabian-Nubian Shield at the northern extremity of the East African Orogen.

It is characterised by a sequence of metasedimentary rocks interspersed with mafic to ultramafic volcanic and intrusive rocks.

Gold mineralisation at Dish Mountain is associated with late-stage, discordant extensional quartz, dolomite, and pyrite veins and their adjacent dolomite-muscovite-pyrite altered selvedges, enveloped by broad dolomite muscovite alteration haloes.

Ashashire’s gold mineralisation is characterised by intense muscovite-dolomite-pyrite alteration adjacent to the mineralised veins, with a proximal to distal intense carbonate alteration halo.

Reserves

The Kurmuk gold project is estimated to contain proven and probable reserves of 60.53 million tonnes (t) grading 1.41g/t gold with 2.74 million ounces of contained gold, as of December 2023.

Mining methods

The Kurmuk gold project is proposed to employ conventional open-pit mining techniques, encompassing drilling, blasting, loading, and hauling operations.

The Dish Mountain pit will be developed in three stages, and the Ashashire open pit will be mined in two stages. The two pits are planned to reach depths of approximately 350m.

Mining will be executed in 9m benches, subdivided into 3m flitches, across four passes at both sites.

The overall distance between berms will be 18m, with presplit drilling conducted in fresh rock. The ramp-up of the mining operation to full production is expected to take 28 months.

The mining fleet will include 200t excavators and 90t rigid dump trucks, accompanied by production drills and a suitable ancillary fleet.

Ore processing

The run-of-mine ore will undergo crushing in a primary jaw crusher.

The crushed ore will undergo grinding in a semi-autogenous grinding and ball mill equipped with a cyclone classification cluster.

The ground ore will then undergo gravity separation, with the fines subjected to intensive cyanide leaching and electrowinning.

The resultant concentrate will be acid-washed and eluted before entering the carbon-in-leach (CIL) circuit.

The CIL concentrate will undergo cyanide recovery and will be acid-washed before being fed to the elution circuit.

The concentrate will then undergo electrowinning, and the final product will be smelted in a diesel furnace to produce dore bars.

Tailings from the CIL tanks will undergo cyanide detoxification and thickening before being transferred to the tailings storage facility (TSF).

Process water will be reclaimed from the cyanide recovery circuit and the TSF.

Site infrastructure

A 12.3km access road will link the Dish Mountain area to the Ashashire mining area, intersecting Highway 40.

The Kurmuk substation will incorporate a 132kV single busbar system, a line bay, and a dedicated transformer feeder bay for mine distribution.

It will also feature two 132kV/11.5kV and 25kV/33MVA transformers and 11kV feeders.

Water will be sourced from a storage dam and pumped to a modular filtration plant and then to the process plant.

Potable water will be provided by three plants located at the process plant, the main camp, and the Ashashire mine service area.

Permanent camps will be constructed to accommodate 798 personnel in the main camp and 178 in a separate security camp.

Contractors involved

The process plant design was developed by Lycopodium, an engineering consulting company, based on metallurgical test work managed by Allied and Lycopodium.

Knight Piesold, a global consulting business, was commissioned by Allied to design the TSF for the process plant and provided a hydrogeological review for the Dish Mountain open pit.

The mineral reserve estimates were prepared by mine planning consultancy, Orelogy.

Engineering company DRA Global was engaged in the early works of engineering, procurement and construction management.