International Battery Metals Ltd. [IBAT-CSE] said Monday it is arranged to raise up to US$15 million from a private placement offering of units priced at $1.00 per unit, with net proceeds earmarked for launching the first direct lithium extraction project in North America.

The company said part of the proceeds will also be used to advance engineering on its second-generation extraction technology and for working capital purposes.

The company said each unit will consist of one common share and one transferable common share purchase warrant. Each whole warrant will entitle the holder to acquire one common share at an exercise price of $1.25 for up to two years from the closing date of the offering.

The company said it will grant the underwriting agents an option to increase the size of the offering by up to an additional 15% of the units sold. That option will be available at any time up to 48 hours prior to closing.

On Monday, IBAT shares eased 1.5% or $0.014 to 92 cents. The shares are trading in a 52-week range of $1.79 and 50 cents.

The mining industry is working to develop direct lithium extraction technologies (DLE) as it races to reinvent how the battery metal is produced for the green energy transition. The expected rise in demand for lithium has sparked widespread interest in DLE technologies, which use less land and can operate far faster than hard rock mining and brine evaporation ponds, the traditional ways to process the white metal.

E3 Lithium [ETMC-TSXV, EEMMF-OTC, OU7A-FSE], for example, sees opportunity in Alberta’s depleted oil and gas reserves. The technology it is testing will, if successful, extract lithium from brine in old wells, material that could eventually find its way into the batteries that power electric vehicles.

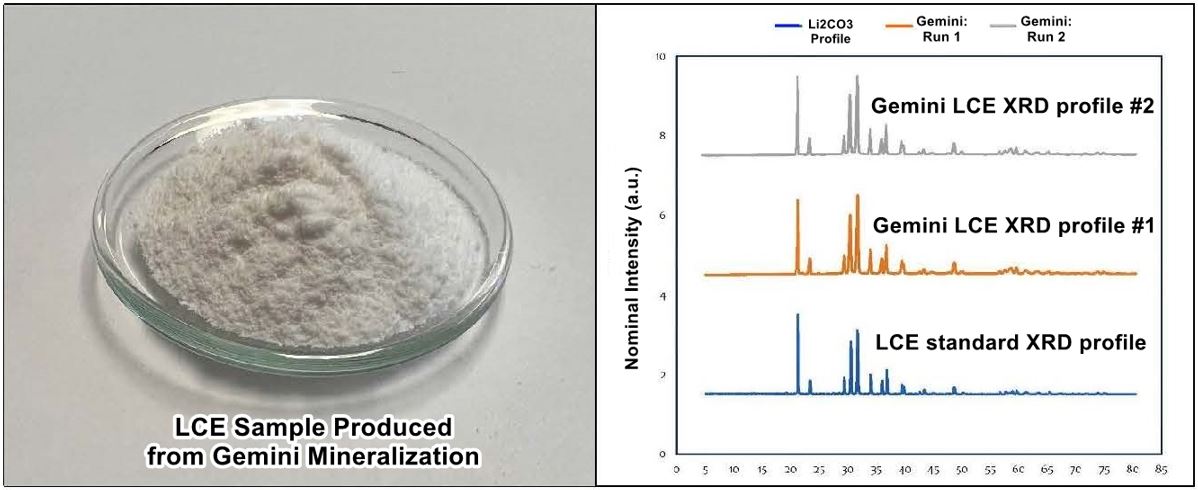

IBAT’s DLE technology is based on proprietary lithium extraction housed in patented extraction towers that are enclosed in a modular shippable platform that can be loaded and brought into production within 10 days of arrival at the customer site.

Some types of DLE technologies require 180 tonnes or more of water to produce a single tonne of lithium, a practise that has sparked controversy in arid regions seeking to conserve potable water and one that has offset DLE’s purported promise of curbing the mining industry’s large water use.

Now, DLE developers are racing to boost freshwater recycling as they fine tune technology, part of a push to ensure they do not lose community support before their industry has the opportunity to go fully commercial.

IBAT’s focus has been on advanced extraction of lithium chloride from ground water salt brine deposits and returning the same water to the subsurface aquifer from which it is extracted.

“If we cannot do a good job of recycling that water and reducing our water footprint, we’re going to get crushed,’’ said International Battery Metals Executive Chairman John Burba. “DLE is a very water intensive process.’’