Alberta Carbon Trunk Line a ‘perfect example’ of a successful carbon capture and storage hub in action

Call it a CCS highway – a shared transportation and storage network that enables multiple industrial users to reduce emissions faster. So-called “hubs” or networks are becoming the leading development strategy for carbon capture and storage (CCS) as the world moves faster to fight climate change, according to the Global CCS Institute.

Alberta, with its large industrial operations and more CO2 storage capacity than Norway, Korea, India, and double the entire Middle East, is an early leader in CCS hub development. “For Alberta, the concept of CCS hubs makes a lot of sense because you have many industry players that are trying to reduce their emissions, paired with beautiful geological opportunities beneath,” says Beth (Hardy) Valiaho, vice-president with the International CCS Knowledge Centre in Regina, Saskatchewan.

Jarad Daniels, CEO of the Melbourne, Australia-based Global CCS Institute, says that historically, CCS would be a single project integrating a CO2 capture plant with dedicated CO2 compression, pipeline and storage systems. “Networks, where each entity typically operates only part of the full CCS value chain provide several benefits,” he says.

“They reduce costs and commercial risk by allowing each company to remain focused on their core business.”

The institute, which released its annual global status of CCS report in November, is now tracking more than 100 CCS hubs in development around the world.

Alberta already has one, and Valiaho says it is a “perfect example” of what she likens to on and off-ramps on a CO2 highway.

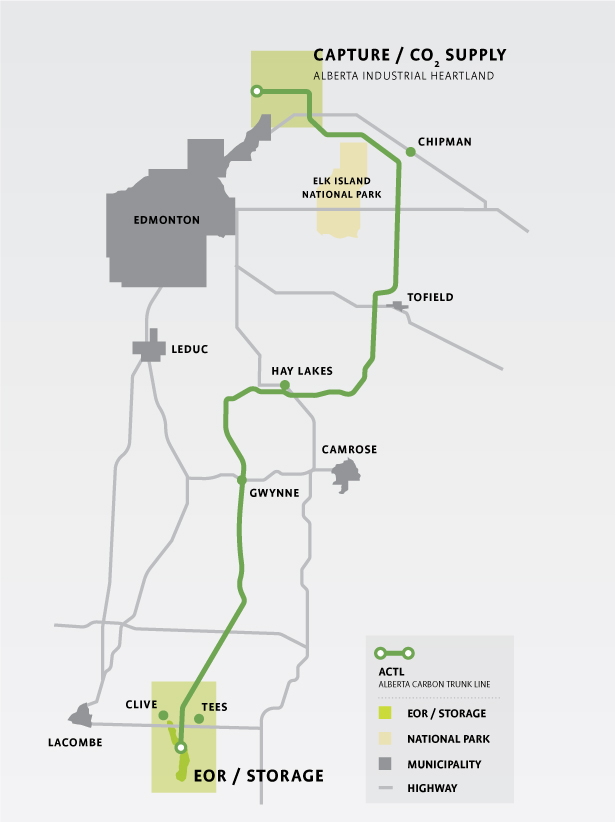

The Alberta Carbon Trunk Line (ACTL) went into service in 2020 as a shared pipeline taking CO2 captured at two facilities in the Edmonton region to permanent underground storage in a depleted oil field.

So far ACTL has transported more than four million tonnes of CO2 to storage that would have otherwise been emitted to the atmosphere – the equivalent emissions of approximately 900,000 cars.

ACTL was constructed with a “build it and they will come” mentality, Valiaho says. It has enough capacity to transport 14.6 million tonnes of CO2 per year but only uses 1.6 million tonnes of space per year today.

The future-in-mind plan is working. A $1.6 billion net zero hydrogen complex being built by Air Products near Edmonton will have an on-ramp to ACTL when it is up and running later this year.

Air Products will supply hydrogen to a new renewable diesel production plant being built by Imperial Oil. Three million tonnes of CO2 per year are to be captured at the complex and transported for storage by the ACTL Edmonton Connector.

Hub projects like this are important globally, Daniels says, as CCS operations need to dramatically increase from 50 million tonnes of storage per year today to one billion tonnes by 2030 and 10 billion tonnes by 2050.

“It’s clear the development of CCS networks and hubs is critical for achieving the multiple gigatonne levels of deployment all the climate math says is required by mid-century,” he says.

Valiaho says Alberta is an encouraging jurisdiction to develop CCS hubs in part because the government owns the geological pore space where the CO2 is stored, rather than developers having to navigate dealing with multiple resource owners.

“Alberta is a model for the world, and the fact that the government has declared crown ownership of the pore space is very interesting to a lot of international jurisdictions,” she says.

There are 26 CCS storage project proposals under evaluation in Alberta that could be used as shared storage hubs in the future, including the project proposed by the Pathways Alliance of oil sands producers.

If just six of these projects proceed, the Global CCS Institute says they could store a combined 50 million tonnes of CO2 per year, or the equivalent emissions of more than 11 million cars.

Share This: