When a large coal mine in Victoria needed help monitoring the temperature of conveyor belt brakes, Madison Technologies was ready with a solution.

An Industry 4.0 enablement partner, Madison Technologies specialises in operational technology solutions architecture, collaborating closely with system integrators and organisations to support deployment.

So when a large Victorian coal mine sought assistance in monitoring the temperature of its conveyor belt brakes, Madison Technologies knew it had the answer.

“Overheating brakes can affect operation of the machinery and lead to breakdown or failure,” Madison Technologies industrial IoT/AIoT program manager Luke Kavanagh told Australian Mining.

“The conveyer belt processes millions of dollars in coal each day and overheating brakes is an early indicator of potential failure or interruption to service.”

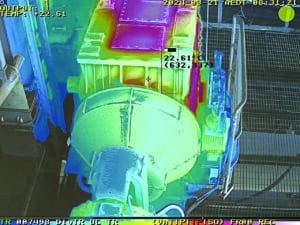

Image: Madison Technologies

Kavanagh explained the problems faced by the coal miner.

“The purpose of these cameras is to monitor the conveyor brake systems for excessive temperatures as an early warning to prevent fires caused by the ignition of coal dust,” he said.

“Typically the brakes are engaged during the last five per cent of a conveyor slow-down/stop event, however there have been cases of failure causing the brakes to engage while at full speed, thus starting fires due to excessive friction and heat.”

To fix the problem, Madison Technologies turned to Mobotix’s thermal cameras, driven by advanced radiometry artificial intelligence (AI).

While it may seem a simple idea, these cameras do more than just capture images; they also monitor, detect and prevent fire hazards in real-time.

The coal miner had previously managed the monitoring itself through camera deployment and experienced issues such as false alarms, affecting the accuracy and confidence in the solution.

“Because each camera is covering a large area in order to monitor multiple brakes, false alarms were being generated due to other heat sources in the scene such as vehicles or over exposure due to surface reflection,” Kavanagh said.

“To help with false alarming, we recommended a specific Mobotix AI app that supports monitoring of up to 20 individual areas simultaneously within the camera image.

“By implementing this edge AI, we set up rules to monitor the brakes individually, which improves specificity, performance and reliability.”

An expert in camera solutions, Mobotix is continuously developing unique solutions for the mining industry. Its new thermal validation app uses machine learning to identify benign heat sources, in turn reducing false alarms.

“Our thermal cameras can monitor up to 20 detection zones with custom temperature settings, enabling early fire detection, preventive maintenance, and human exclusion zones within the same field of view,” Mobotix vice president sales APAC Ryan Philp told Australian Mining.

“With modular design, edge processing, in-house app development, key AI partnerships and various communication protocols, we can create tailored solutions for the most complex requirements.”

Mobotix holds five unique certifications for early fire detection using its thermal cameras, including internationally recognised standards. This adherence to safety was one of the main reasons Madison Technologies recommended the Mobotix app to the coal miner.

“Preventive maintenance and early fire prevention through our technology detects anomalies before they are visible to the human eye, potentially saving companies millions in production, but also in lives,” Philp said.

“Additionally, these measures significantly enhance worker safety, a critical priority for companies aiming to protect their employees and maintain their reputation.”

The further benefits of deploying Mobotix thermal cameras are far-reaching.

On top of receiving real-time monitoring and alerts, the coal miner also saw enhanced safety metrics and regulatory compliance, operational efficiency and predictive maintenance, and increased sustainability and energy management.

The role of technology in the mining industry is constantly evolving, transforming the way the sector protects its workers and its profits. And Madison Technologies is constantly working on developing new and innovative ways technologies can be used to help the sector achieve its goals.

“Robust communication networks ensure seamless connectivity across mine sites, enabling real-time data access and sharing,” Kavanagh said. “This is crucial for remote-monitoring and immediate hazard response, and boosts safety standards significantly.

“Strong communications networks bridge the physical with the digital, underpinning every aspect of modern industrial operations, from basic device communication to the complex orchestration of entire operational networks.”

In addition to these networks, Artificial Intelligence of Things (AIoT) and Industrial Internet of Things (IIoT) play a vital role in optimising mining operations.

“Traditional sensors have provided necessary data for monitoring and control, but as demands for accuracy, integration and real-time analysis increase, the industry is pivoting towards more advanced solutions,” Kavanagh said.

“By leveraging predictive analytics, these technologies enable timely maintenance, reducing unexpected downtime and ensuring equipment reliability. They also allow for real-time monitoring of environmental conditions and machinery health, providing actionable insights that enhance operational efficiency.”

Camera-based sensors are just one example, but this relatively simple technology has saved the Victorian coal miner thousands of hours of work.

“These sensors not only capture images but also collect rich visual data that can be analysed to inform and enhance decision-making processes,” Kavanagh said.

“The multitude of connected devices in operational environments drives safer, more productive and sustainable mining operations by enhancing data access, connectivity and intelligent decision-making.

This feature appeared in the July 2024 issue of Australian Mining.