An underground coal mine has seen a major boost with a switch to Flexco’s XP Staple Belt Fastening System.

Flexco was recently tasked with helping the team at an underground coal mine in Australia that was experiencing increasing maintenance costs due to frequent fastener replacement.

The site’s previous belt fastening solution was continuously wearing out quickly, causing production stoppages and leading to excessive downtime and repair costs.

Flexco New South Wales territory manager Franklin Moore, alongside a trusted distributor, met with the site manager to further discuss their pain points, eventually suggesting a test trial with the XP Staple Belt Fastening System.

“The XP Staple Fastening System is an innovative solution from Flexco that is having a profound impact on the heavy-duty mining sector,” Moore said.

“We went into product development with the goal of producing the longest-lasting staple fastener and hinge pin system on the market, and I believe our team has accomplished that.”

There are some exciting features with the XP that promote strength and performance. For one, its larger loop area allows for bigger pins, which improves the life of the belt splice.

Additionally, the use of cold rolled steel significantly helps to increase tensile strength. Overall, the XP boasts a fastener rating from 800–2000 pounds per inch of width, making it a great choice when strength is a main requirement.

The site’s main goal in conducting a test trial was to find a solution that extended its fastener lifespan.

To accurately and fairly determine the difference between fastener performance, both the XP and the competitor’s fastener were installed on the same conveyor and in the same position, further ensuring that they faced the same applicational conditions.

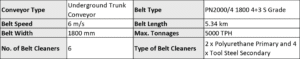

The following are the trial specifications:

It was decided that both fasteners would stay on the belt until their performance fell outside of the acceptable range of the competitor’s triggered action response plan (TARP).

After three weeks, the competitor’s fasteners were deemed unusable.

At 17 weeks, Flexco’s XP staple fasteners were switched due to a scheduled belt replacement, despite still being within the TARP range and capable of extended use.

“We couldn’t be more proud of Flexco’s performance in this trial run,” Moore said. “To see a difference of 14 weeks in the runtime between the two fasteners is astounding.

“Not only will the time the operation will save directly lead to a reduction in repair costs, but it also gives their maintenance team time back that they can use to address other pressing tasks around their facility.

“The XP has truly set itself apart as the premier choice for splice reliability below the surface.”

Both the conveyor maintenance site representative and the on-site service crew expressed satisfaction with the XP after the trial was completed.

They were able to report back to their leadership team with a tangible solution that provided effective results and allowed them to focus maintenance efforts elsewhere.

The XP Staple Belt Fastening System is ideal for solid woven PVG/PVC belting used in heavy-duty applications like underground mining, coal, and open pit/hard rock mining.

Fasteners are available for belt sizes ranging from 6mm to 20mm thick after skiving, and for pulley diameters from 250mm to 500mm.

For more information on the Flexco XP Staple Belt Fastening System or any other heavy-duty belt conveyor solutions from Flexco, visit www.flexco.com.

_Logo_Color.jpg)