Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Daimler Truck North America has announced a $285 million investment at its Detroit Diesel subsidiary. “The proposed investment involves modernizing and enhancing the current plant to maintain its existing production capacity while expanding and equipping it to manufacture electric components for medium and heavy duty electric trucks,” according to a statement by the Michigan Economic Development Corp.

Perhaps you are one of those people who thinks the words “Detroit Diesel” and “electric powertrain” do not belong in the same sentence. There are plenty of folks who get all jiggly at the thought of a massive diesel engine pumping out 2000 foot-pounds or more of torque at 300 rpm as it hauls 80,000 pounds of freight up to the Eisenhower Pass west of Denver. Diesels today have become part of American mythology, the way cowboys were 100 years ago. In fact, we are told by more than one source here at CleanTechnica global headquarters that some diesel lovers are rending their garments over the news. What they seem not to realize is that Detroit Diesel manufactures powertrains for Freightliner and Western Star trucks and Thomas Built Buses.

Detroit Diesel & Electric Trucks

Freightliner is already deeply involved in the development of battery-electric Class 8 tractors. Earlier this year it unveiled a prototype eCascadia with integrated self-driving technology. The company is pursuing a vision of zero emissions and increased road safety by combining the two most promising technologies to deliver on that vision — battery-electric drive and integrated autonomous driving technology — in one semi-truck for the first time in its history.

The autonomous Freightliner eCascadia technology demonstrator is based on a production battery-electric Freightliner eCascadia and is equipped with Torc’s autonomous driving software and the latest Level 4 sensor and compute technology. Torc Robotics is Daimler Truck’s independent subsidiary for autonomous virtual driver technology. While still a research and advanced engineering project, the autonomous vehicle has the potential to evolve into a modular, scalable platform that is propulsion-agnostic for flexible use in different trucking applications with a goal of offering customers the right vehicles for their specific business and transportation needs. The technology is now being tested on the road in Texas.

Thomas Built Buses is one of the largest supplier of electric school buses in America, although that market may not expand as quickly as it should once the Trump transition team gets done eviscerating federal tax credits. Can’t have electric school buses draining much needed money away from tax cuts for the 804 billionaires in the US. They paid to get the Tangerine Buffoon elected and they damn sure expect a sizable return on their investment.

The money Daimler Truck North America is providing to Detroit Diesel is expected to create up to 436 jobs and preserve about 2,000 more at the company’s factories in Redford Township and in Detroit, which produce engines, transmissions, and axles for the Freightliner, Western Star, and Thomas Built Buses vehicle platforms, according to a news release. The state of Michigan is kicking in incentives of more than $30 million in the form of a state grant and a tax abatement.

Matt Pfaffenbach, the company’s vice president of powertrain operations, said “this expansion is about more than just innovation; it’s about creating job opportunities and up skilling our workforce to meet the demands of tomorrow’s technology, while helping to stabilize the heavy duty supply chain.” Wayne County Executive Warren Evans cheered the announcement as “a huge win for one of our older, core communities as we continue to take Wayne County’s economic development to the next level.” The memo from the Michigan Economic Development Commission noted that 335 of the new jobs would be hourly production positions with an estimated median wage of $25.86 based on the current UAW contract, and that the remaining 101 jobs would be salaried employees — mostly engineers — with an estimated median annual salary of $113,000.

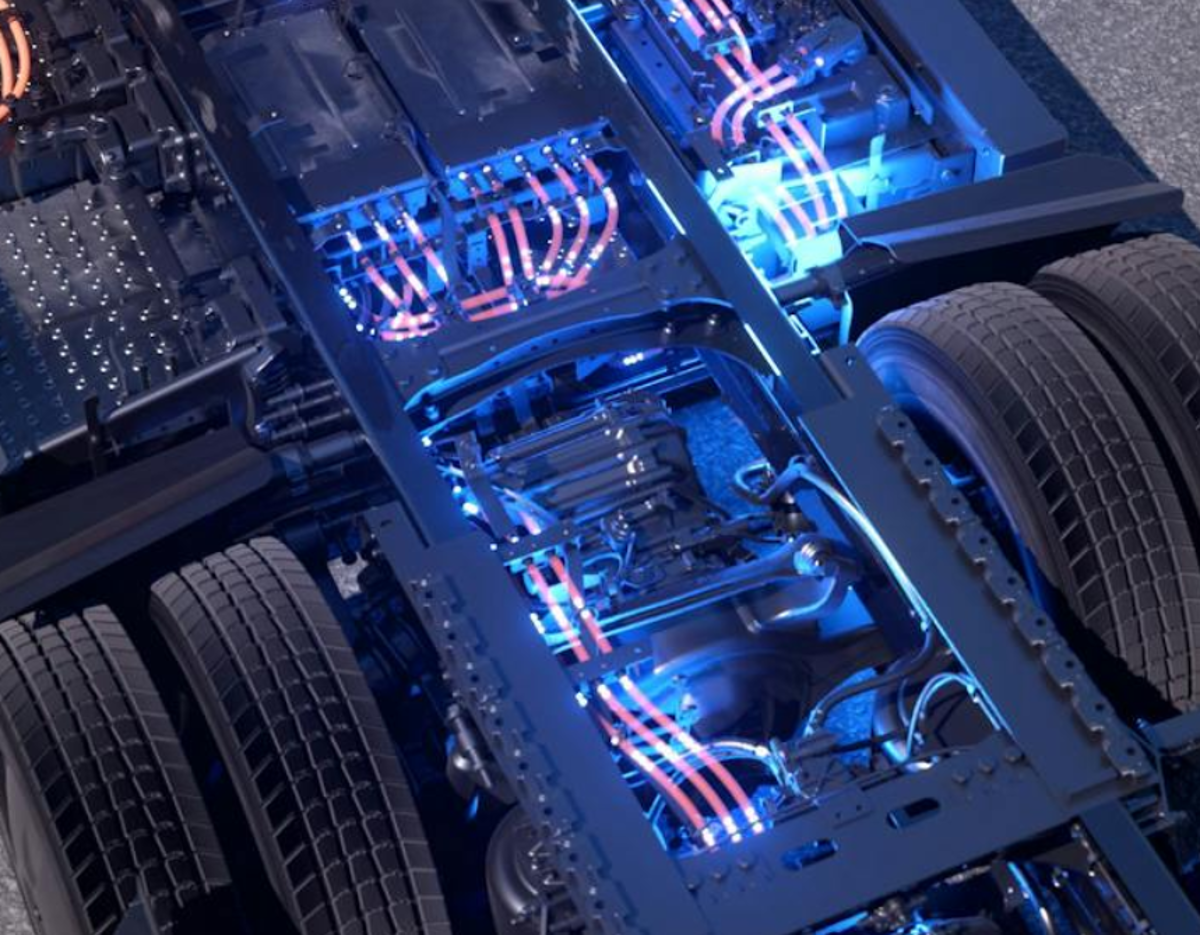

Daimler Truck North America is pretty chuffed about its new electric powertrains, which it calls purpose built and seamlessly integrated for power, efficiency, reliability, and zero emissions. “At Detroit Deisel, we push the limits of productivity and sustainability every day, and we’re ready to provide the expertise and support you need to do the same. Lose the emissions and gain so much more. The Detroit Diesel ePowertrain electric axle provides maximum torque to get loads moving as well as quick, smooth acceleration on the road. Get ready for an all electric workhorse that drives efficiency and compromises nothing.”

The Detroit ePowertrain has Detroit eAxles and batteries that work together efficiently to integrate seamlessly with the company’s connectivity and safety systems. It all adds up to a smart and complete Detroit Diesel solution that provides ultimate performance, maximum efficiency, and lower costs for electric trucks. An eAxle is an electric drivetrain component that is the key to making a battery-powered truck less complex and more productive. By integrating an electric motor, transmission, and specialized electronics within a compact unit, the eAxle can directly and efficiently power a truck’s wheels. The Detroit Diesel ePowertrain provides two eAxle designs to meet the demands of any job.

Performance Means Different Things To Different People

Performance is a relative term. To a drag racer, it means doing the quarter mile in under 10 seconds. To a sports car driver, it means having a car that hugs the curves. To a trucker hauling a loaded trailer, it means enough torque to handle full loads. The Detroit Diesel ePowertrain can be ordered with either a single of a dual eAxle. The dual motor version has 395 horsepower, which may not sound all that impressive to some, but here’s a number that might. The dual motor version has a whopping 23,000 foot-pounds of torque. For our readers outside the US, that translates to 31,184 Nm. That should be more than enough to haul a fully loaded trailer up the Rocky Mountains without breaking a sweat. The single motor versions have half the horsepower and half the torque. Several battery packs are available to suit the needs of various customers. The smallest is 194 kWh, which provides up to 4 hours of operating time, depending on the load being transported. 291 kWh and 438 kWh battery packs are also available for journeys of up to 6 hours.

Diehard diesel fans bemoan the coming era of electric trucks, just as many wagon makers bemoaned the advent of paved roads and the automobile. There are always those who have an irrational fear of the future. We survived the internet and the smart phone. Chances are we will survive the advent of electric trucks as well. After all, if we don’t find ways to decarbonize human society, we won’t need any trucks because there won’t be any people alive who can afford to buy the goods and products they deliver. Detroit Diesel is not burying its head in the sand and wailing about the good old days. It is seizing the opportunity to design and build the trucks we will need for a low carbon future.

Hat tip to Jock Gill

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy