Natural gas dehydration is essential in many processes due to the presence of humidity in varying concentrations. Liquid water and hydrate formation will have an extensive impact on safety and operational reliability. Frozen control valves or plugged orifices can cause a complete shut-down.

A common way to dehydrate gases is the use of a glycol dehydration unit. The hygroscopic characteristic of Tri ethylene glycol and the high boiling point compared to water makes TEG an ideal dehydration agent.

Improvement of safety and efficiency in dehydration.

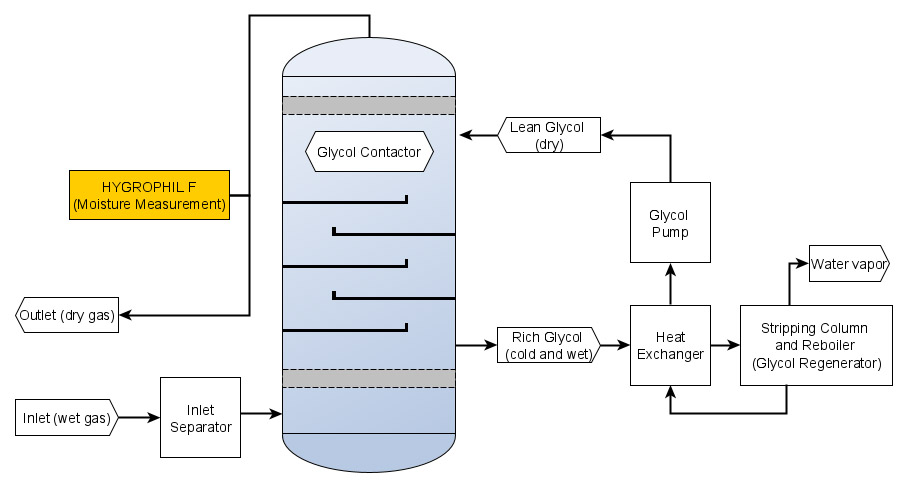

Liquid components are separated in an inlet scrubber before the natural gas enters the Glycol contractor unit. In the contractor, the gas is flowing from the bottom to the top where it passes several stages of trays and bubble caps. Lean (dry) glycol is fed from the top and flows downwards from tray to tray whereby the water vapour gets absorbed due to the hygroscopic properties of the Glycol.

The dehydrated natural gas leaves at the top of the contactor tower after passing a mist eliminator to reduce glycol loss. The rich (wet) glycol leaves the contractor near the bottom and passes a heat exchanger towards the glycol regenerator to warm up. Within the stripping column and reboiler the absorbed water is separated from the glycol by distillation. The regenerated and hot glycol flows again through the heat exchanger to reduce the temperature after regeneration. The glycol pump is used to circulate the liquid desiccant within the unit.

Figure 1: Diagram of a simplified glycol dehydration unit

The water removal rate is depending on many factors such as:

- Gas and glycol temperatures

- Gas flow rate and specific gravity

- Operating pressure

- Inlet water content

- Glycol circulation rate

- Condition of the glycol (impurities)

- Mechanical or chemical issues (foaming)

- Corrosion cause by NACI, H2S, and CO2

- Blocked filters, fouled heat exchangers or failing pump

Reliable humidity measurement in the outlet gas is essential to ensure proper dehydration to meet sales gas criteria or prevent hydrate formation in the connected pipelines. Monitoring the moisture level continuously helps to improve the operation in terms of energy saving by reducing the glycol circulation rater and reboiler temperature. In addition, the detection of approaching problems in an early stage helps the operators to plan the maintenance within reasonable intervals.

The Hygrophil F is designed for the needs of the natural gas industry.

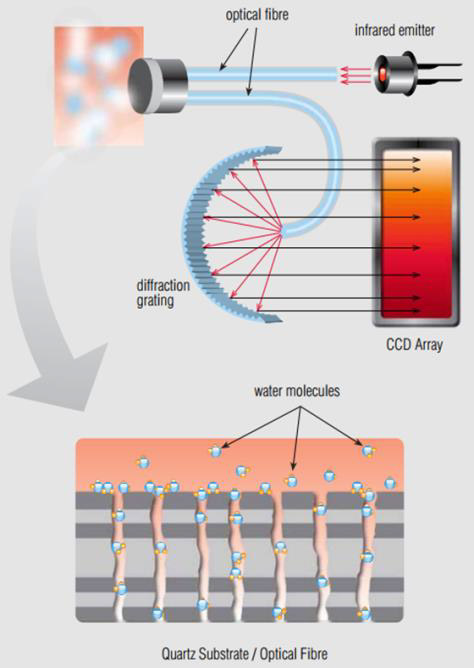

The core element of the moisture sensor is an optical thin film element made of silicon dioxide and zirconium dioxide. The microporous stack of alternation high and low refracting optical layers if forming a Fabry-Perot Interferometer with a distinctive and reliably detectable reflection minimum in the spectral range around 820 nm.

Selective to water, molecules can diffuse into the porous Fabry-Perot element, which then performs a shift of the reflection minimum in proportion to the actual water vapour pressure. The spectral shift is detected and evaluated with a compact high-resolution polychromator, which is located in the evaluation unit together with the light emitting diode. The interconnecting fiber optic cable can be up to 800 m long because of the detection of an optical minimum instead of an intensity change.

The evaluation unit processes and calculates the present dew point temperature as well as other units such as water vapour pressure, parts per million, mg/m3 and furthermore it offers the indication of the dew point temperature at current line pressure as well as to different defined reference pressure. Optionally the calculation from dew point temperature to mg/m3 can be done in conformance to DIN EN ISO 18453 which takes respect of the entered gas composition.

Several analog outputs, MODBUS, PROFIBUS RTU and TCP/IP as well as relay contacts are equipped as standard interconnection to the control system.

Thousands of installations worldwide prove the advantage of this measurement principle:

- Robust sensor construction for outstanding long-term stability

- Condensation or Glycol carryover does not damage the sensor

- Easy sensor cleaning and almost no maintenance required

- In-line installation with sensor retraction armature possible (fast response and emission-free)

- Flexible on-line solutions with customized sample condition systems

- Certified for safe operation in hazardous area (ATEX, IECEx, CSA, TR CU)

Are you looking to enhance safety and operational reliability in your natural gas dehydration process? Discover the advanced BARTEC HYGROPHIL F 5674 Process Trace Moisture Analyzer from Westech Industrial today!

🌐 Visit our website to learn more about the BARTEC HYGROPHIL F 5674: https://bit.ly/3DoYf8M

📞 For inquiries and orders, call us at 1-800-912-9262.

The BARTEC HYGROPHIL F 5674 is designed specifically for the natural gas industry, providing reliable humidity measurement in outlet gas to ensure proper dehydration and prevent hydrate formation. Its optical thin film element made of silicon dioxide and zirconium dioxide offers outstanding long-term stability and immunity to condensation or Glycol carryover, making it a robust and low-maintenance solution for your dehydration units.

Improve safety, efficiency, and energy savings in your gas dehydration process today with the BARTEC HYGROPHIL F 5674 Process Trace Moisture Analyzer. Don’t miss out on this proven measurement principle used in thousands of installations worldwide.

Take the next step towards optimized gas dehydration—explore the BARTEC HYGROPHIL F 5674 now: https://bit.ly/3DoYf8M

📞 Call 1-800-912-9262 for more information and to place your order. Experience the Westech Industrial advantage today! 🛠️🌐

Share This: