Thejo’s range of mineral processing and bulk material handling products and services is helping Australia’s mines keep on track.

Since launching into the Australian mining sector in 2012, Thejo has established a strong reputation, which, as Thejo Australia chief operating officer Andrew Thompson explained, is in part thanks to the legacy of the international brand.

“Thejo Engineering has a worldwide footprint spanning India, Brazil, Saudi Arabia, the United Arab Emirates, Chile and Australia,” Thompson told Australian Mining. “Since Thejo Australia launched, we’ve been offering solutions that have been tested and perfected across the globe.”

Thejo Engineering started out in India 50 years ago with a commitment to developing next-level mineral processing and bulk material handling solutions.

Research and development (R&D) has always been a central focus for Thejo, and the company’s Australian arm is no different.

“We have been busy expanding our capabilities to bring our solutions to more mines,” Thompson said. “Our expanded product offering covers every aspect of mineral processing and bulk material handling equipment.”

Whether it’s chute lining, mill lining, screening, filtration and dewatering systems, corrosion protection, rubber lining, or a complete range of conveyor belting and conveyor care products, Thejo and its team of engineering experts are pushing to take the next leap in product evolution.

“We’re continuing to invest in R&D and product development,” Thompson said. “The vision of our founders has always been to be a world-class company.

“That’s why we undergo rigorous product development and testing to ensure we’re giving our customers top-tier solutions.

“Our mission is to combine a commitment to quality and a well-designed and built product with flexibility and a timely delivery to market.”

Thompson said regular inspection and maintenance plays a critical role in increasing the service life of any asset.

“Predictive, real-time remote monitoring can be used to minimise unplanned downtime,” he said. “Through industry partnerships, Thejo is able to offer real-time monitoring equipment for abrasive wear in multiple applications, including mill lining and conveyor belts, while a belt cleaner monitoring system is under site trial as we speak.”

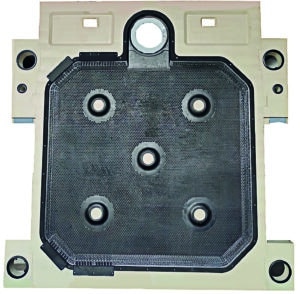

Image: Thejo

Thejo’s range of products features conveyor belting and components, installation equipment and vulcanisers, and transfer chute design, repair and replacement, including wear liners, dust suppression and flow promotion.

The company also offers comminution equipment such as liners for mills, pulp lifters, trommel design and supply, all types of screen media and accessories, as well as consumables for filter presses, and slurry handling pipes, spools and hoses.

But it’s not only products where Thejo is investing resources. The company’s services arm is providing its customers across Australia with complete material handling packages for the design, construction, supply and maintenance of conveyor systems and rubber linings.

This includes belt splicing, repair, pulley lagging and a complete belt replacement service. Thejo has over 40 trained belt and mechanical technicians employed full time including a supervision team ready to be deployed to site as needed.

The company takes a holistic approach to its services, with designated operations, health and safety, training, and management teams to support its service crews in the field.

It’s an approach Thejo carries into its comprehensive rubber lining products and services, where the company provides both hot- and cold-applied rubber lining, including rubber-backed ceramic tiling, to provide suitable protection for plant equipment.

“We supply rubber linings for the most aggressive mining and quarrying applications,” Thompson said. “The benefits of rubber lining for this industry include high resistance to abrasion and corrosion, noise reduction, increased plant life and reduced downtime.

“Our customers know they can count on us to be available when they need us.

“We’re always responsive to enquiries and work with our customers to keep their conveyors and linings on track.”

This feature appeared in the September 2024 issue of Australian Mining.