IO-Link technology is shaping up to transform the way modern mining is done.

Digitalisation, automation, and data-driven decision-making are no longer just industry buzzwords; they are transforming the modern mining industry.

Mining is rapidly becoming a sector shaped by digital connectivity, and IO-Link is one technology shaping that future.

Developed by a global consortium of over 300 companies, IO-Link is a communication standard that is revolutionising data access in the resources industry, unlocking a wealth of new operational data and empowering more informed decision-making.

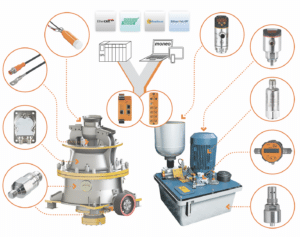

Acting as the eyes and ears of the entire mining process, IO-Link interconnects all aspects of an operation, including digital sensors, enabling the collection of inter-machine data across the entire production chain.

As a pioneer in IO-Link development, ifm is now collaborating with mining operators across Australia to leverage the power of digital connectivity, optimising their processes for enhanced efficiency and productivity.

“While traditional sensors provide values such as pressure or temperature, digital sensors deliver a comprehensive picture by capturing data across multiple parameters,” ifm industry specialist mining Sam Rupasinghe told Australian Mining.

“IO-Link seamlessly handles connectivity, whether it integrates new sensors and instruments or incorporates existing ones into a digital system. This makes it a cost-effective way to future-proof mines without requiring a complete infrastructure overhaul.”

Image: IFM

A leading force in the mining sector’s digitalisation, ifm has been developing and manufacturing standard sensors for decades.

Recent advancements have seen ifm incorporate an IO-Link digital chip into standard sensors. This can be activated by operators at any time to leverage the latest digital technologies without replacing entire sensors.

“As the mining sector embraces digitalisation, ifm is leading the way by offering future-proof standard sensors that come equipped with an embedded IO-Link chip, allowing operators to seamlessly activate digital capabilities whenever they’re ready,” Rupasinghe said.

“This eliminates the need for complete sensor replacements, making the transition to a smarter mining operation smooth and cost-effective.”

By using an IO-Link master, operators can connect devices along a more reliable and accurate digital communication path.

“You can have a signal going directly to an existing programmable logic controller (PLC) and communicate with existing protocols,” Rupasinghe said. “Simultaneously, you can launch into the Internet of Things (IoT) to communicate online.”

IO-Link supports multiple outputs, so operators can adjust to the new technology by receiving digital data while also continuing to receive standard analogue signals separately.

Once activated, IO-Link can incorporate artificial intelligence (AI) software capable of detecting anomalies across the entire process chain before they become an issue, taking condition monitoring to a whole new level.

“Data is continuously transmitted from a digital sensor, which then diagnoses possible events,” Rupasinghe said. “For example, the IO-Link monitors sub-systems within mining machines like lubrication, hydraulics, motors and pumps and triggers automated maintenance actions as needed.”

IO-Link, Rupasinghe said, is a technology not an ifm product, which means users are not locked into a particular provider.

“You can use sensors from other providers connected to existing control systems on-site,” he said. “From there, other technologies like Bluetooth and telemetry can be used to access data at any time.”

IO-Link has open data and inter-system connectivity through various gateways, as well as OPC Unified Architecture with solutions like ifm’s Moneo software.

Versatility is a key feature of IO-Link. Understanding that every second counts in fast-paced industries such as mining, IO-Link strives to connect an entire site through real-time data at the touch of a button.

By getting more information than ever out of existing systems without the cost associated with a major infrastructure overhaul, IO-Link technology is setting up operators to take control of their data like never before.

This feature appeared in the April 2024 issue of Australian Mining.