4D Delta provides remote asset inspection services for ore-processing assets, leading to an array of safety and operational benefits.

A picture is worth a thousand words.

It’s a saying as old as time, but in the case of 4D Delta and the company’s advanced 3D wear monitoring technology, it rings true.

Founded in 2014, 4D Delta inspects critical ore processing assets in mining and related industries, including transfer chutes, surge bins, impact plates, grinding mills, crushers, and more.

The company conducts wear monitoring through a unique combination of cutting-edge remote sensing technologies and its own purpose-built software to inspect sacrificial wearing parts of ore-processing plant.

“3D laser scanning is typically an instrument for surveyors or engineers that creates a 3D digital copy of the surrounding environment,” 4D Delta chief executive officer Garth Johnson told Australian Mining.

“They set up a 3D laser scanner inside an environment such as a building and several scans are taken inside and outside. When all the scans are combined you get a point cloud, which is an accurate and highly detailed digital representation of that building.”

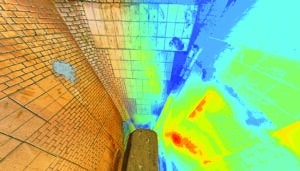

Image: 4D Delta

4D Delta carries out a “very niche application” of 3D laser scanning.

“Generally, a mine site is where bearing ore is drilled and blasted, put onto a truck and taken to a processing plant where it is crushed down to a certain size. That processed ore is then transferred by train to the port and then shipped for further processing where it is turned into the end product,” Johnson said.

“But the rock is so hard that everything it touches in this process will slowly, and sometimes rapidly, wear away over time. The problem with this is you can’t have these multi-million-dollar ore processing assets being exposed to the ore and wearing away to absolutely nothing, otherwise the operator will have to replace the whole asset, which is very costly.

“This is why miners put a protective liner inside the asset, so it’s the lining system that wears away rather than the machine itself. Where 4D Delta comes in is the inspection of those protective lining systems.”

Traditionally, carrying out wear-liner inspections can be an extended and dangerous process for maintenance personnel.

This is why 4D Delta carries out inspections remotely by using 3D sensing technologies such as 3D laser scanners. This way human risk and error is eliminated, safety is optimised, and time is saved.

“When we put these 3D sensors inside the asset, the sensors can accurately scan every surface of the protective liners in high detail, generating rich amounts of data.”

4D Delta’s core capability isn’t the 3D sensing technology itself, but the processing, display and analysis of the 3D data gathered by the sensors. The company does this through its software platform, 4D Delta Cloud.

4D Delta Cloud provides a highly organised and interactive platform for engineers and planners to view and interrogate wear liner inspections. With advanced predictive algorithms, this information can help prevent liner failure while optimising maintenance schedules and asset performance.

“The analysis of that information makes decision-making more objective,” Johnson said.

“When the user clicks on the asset in 4D Delta Cloud, they can access hi-definition 360° images with precise wear map overlays to make reliable assessments of wear liner condition.”

These visuals and scans can be accessed anywhere at any time through any computer, tablet or phone with an internet connection.

4D Delta Cloud also generates interactive reports that detail how the asset will wear and look over time. This will assist maintenance planners in detailing instructions including when to repair or replace the protective lining and what new stock to order.

Having such specific instructions eliminates unnecessary costs and waste.

“The information is continuous,” Johnson said. “If anybody questions the decisions made, the 4D Delta Cloud user can quickly backtrack to any inspection, report or maintenance plan and say, ‘This is why we made this decision’.”

4D Delta’s mission in the mining industry is in its name, literally.

“4D is space and time,” Johnson said. “And delta means change, so our name means ‘the change in space over time’. And that’s what we do, measure the change in wear liner condition over time.”

This feature appeared in the March 2024 issue of Australian Mining.