After several years of recovery, a recent forecast from Baker Hughes predicted a single digit slow down for 2024 in Oil Field Services spending in North America. OFS companies will likely face increasing price pressures which will place even more focus on operational efficiency to drive return on assets. Equipment maintenance is a critical component when it comes to improving operating efficiency and cost. It is estimated that Oil Field Services companies will spend roughly $20 billion this year in maintaining the equipment they provide to their customers.

Increasing Complexity Drives Increased Costs

Oil field services equipment is becoming increasingly sophisticated and technologically advanced. While these advancements enhance operational efficiency, they also introduce complexities that contribute to higher maintenance costs. Complex equipment requires specialized skills for maintenance and repair, leading to increased labor costs.

The shortage of skilled personnel in the oil and gas industry adds to these maintenance challenges as well. Insufficient training programs and a lack of skilled technicians can result in subpar maintenance practices, leading to increased wear on equipment and higher repair costs. Most OFS companies are still supporting their field and maintenance teams with paper work instructions and training, which slows down onboarding and limits usability on the job when the information is most needed.

Excessive Wear and Misuse Costs Are Not Easily Recovered

Oil field services equipment faces harsh operating conditions and the demanding nature of the tasks they perform take a toll on equipment, no matter how well designed and manufactured. However, customer misuse, which could involve improper operation, inadequate maintenance, or operation outside recommended guidelines, can exacerbate the rate of wear and lead to increased repair costs.

While it may be common to include protections in OFS equipment contracts for excessive wear or misuse, it is an entirely different matter for OFS companies to accurately and efficiently recognize the cost of repairs that might be recovered from their customers. Companies still using paper for frontline operations often lack accurate and verifiable repair data, or suffer long delays in collection and analysis that prevent recovery of these repair costs from customers.

EnerCorp’s Digital Post Job Inspections Ensure Recovery of Repair Costs

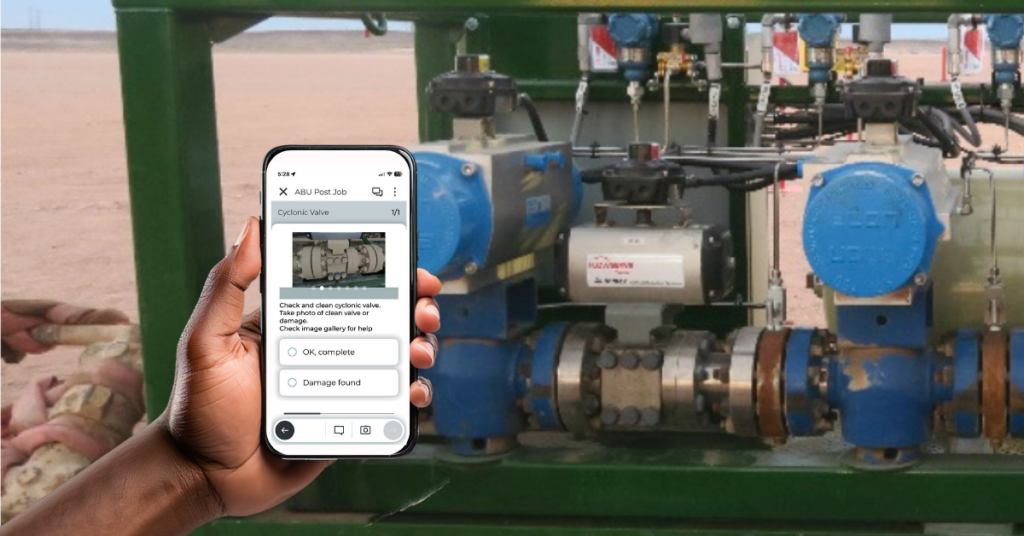

Providing digital post job inspections for maintenance teams is an effective way to address the shortcomings of paper on the frontline, and to help recover costs of excessive wear from customers EnerCorp, an innovative supplier of Sand Management and eFlowback services, digitalized their pre and post job inspection processes to help lower maintenance costs and improve operating efficiency. Digital workflows on mobile devices guide their workforce through standardized inspection processes and make micro-training available for the workforce right at the point of need.

Images and comments from the inspections and repair process are captured along with replacement parts and costs, which are automatically packaged into customer ready documents that are used to charge back customers for repairs not covered by contract pricing. In addition, a history of all inspections, issues, repairs and costs is automatically created for every piece of equipment, providing the asset management team with valuable data to continue to understand and optimize the true cost of operation for every equipment type across the regions they are deployed. More information about EnerCorp’s digitalization project is available here.

The Time Is Right For Digitalizing The Frontline

With increasing pricing pressure, skilled labor scarcity and growing equipment complexity, it is clear that the tools of the frontline workforce need to be modernized. The good news is that today workers are not only more comfortable with digital apps on mobile devices, the next generation of frontline workers expect these types of resources to be available to them on the job. Digitalizing post job inspection processes to improve repair cost recovery is just one example of the benefit of a digital frontline. Digital tools are being used in OFS to drive efficiency in the field to reduce unplanned downtime and lower costs through regular preventive maintenance. Training and safety instruction can be more easily and effectively delivered, and compliance more easily ensured as well. And digital tools are automating the collection of critical equipment data and maintenance activities that OFS companies can use to continue to drive operational efficiency.

Stephen Zocchi is CMO at ROO.AI. After building software to help salespeople quickly and easily price and configure complex equipment, he joined ROO.AI to create a new mobile platform to guide and assist frontline workers in Oil & Gas and MTO Manufacturing.

Share This:

Next Article