Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

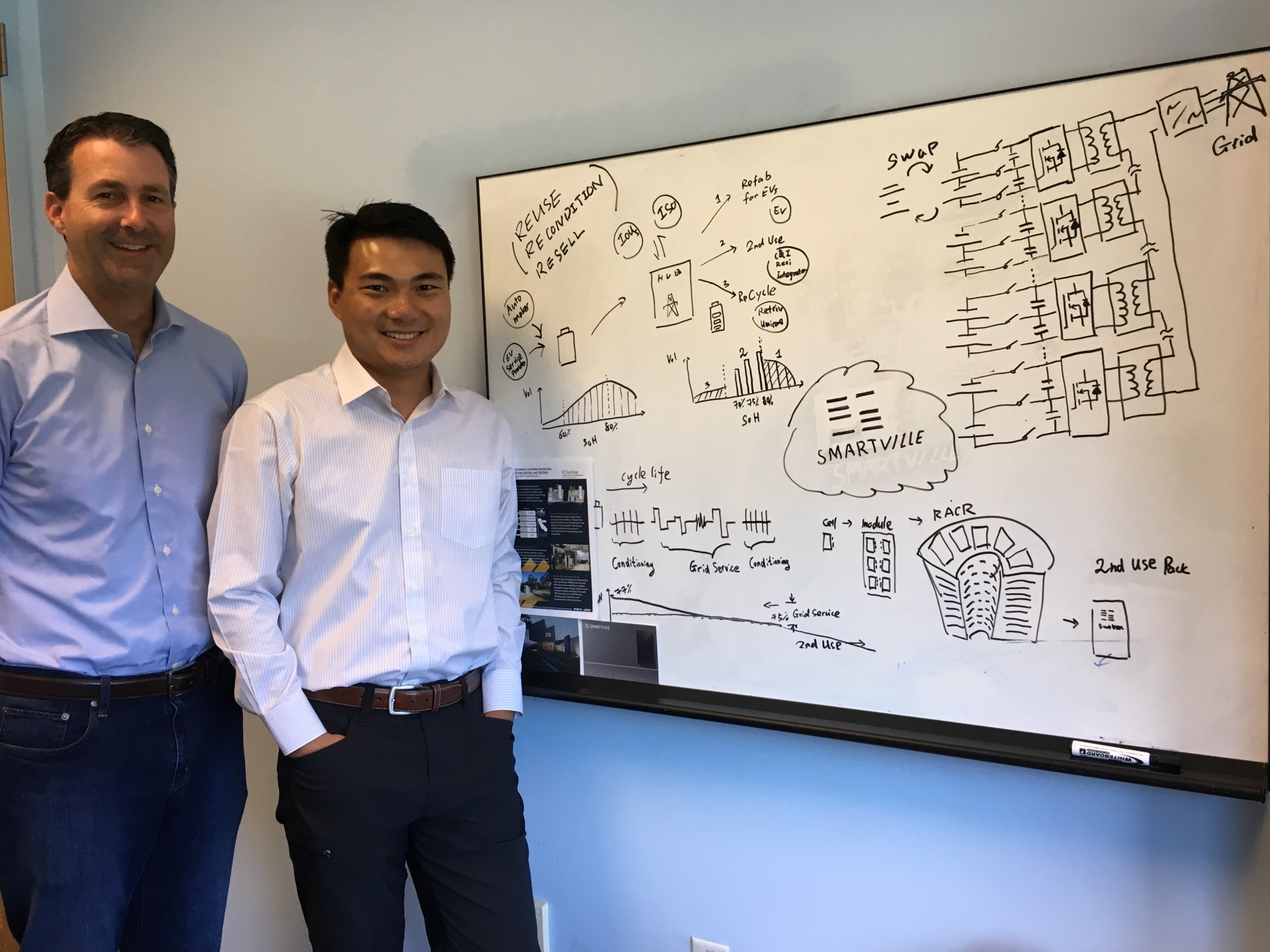

Smartville emerged as the product of of the University of San Diego, California, as a result of the research of co-founders Antoni Tong and Mike Ferry. They realized the need for and the opportunity to build a business around triaging and repurposing second life electric vehicle batteries.

Ferry is the Director of Energy Storage & Systems at the university and Tong was a research scientist and as part of their work at the university, they developed what would become the building blocks of a company that would eventually become Smartville.

One Tool To Rule Them All

The opportunity to put used EV batteries to use as stationary energy storage systems has been talked about for ages, but as with most things, building a product from the vision is much harder to do. The secret sauce at Smartville doesn’t start with the batteries, complex chemistries, a novel recycling process, or even battery cell management, but rather, in the digital realm with a software solution. Tong and Ferry built a tool to quickly assess the health of automotive batteries with a two step triage process.

First, they connect their briefcase-sized assessment tool to a battery pack to determine if it’s healthy or not. This quick triage is a high level test to determine the health of the battery cells themselves, the battery management system (BMS), thermal management systems, and communications systems of the pack. Their compact tool is unique in that it is almost purpose-built to work in salvage operations to quickly determine if the battery is able to be sent back to the automotive market as a used but serviceable replacement battery, used in Smartville’s second life energy storage solutions, or broken down fully for bottom-up recycling.

It is still early days when it comes to processing massive quantities of used EV batteries, but with EVs representing an ever increasing percentage of new car sales, the need is already growing. Today, the main battery packs in EVs that make it to salvage yards are considered risky and potential fire hazards. The battery health assessment tool from Smartville could potentially be invaluable for salvage yards and the secondhand automotive market as a whole. It very quickly allows operators to determine if a pack is safe or not and if it is, what the value of the pack is. Determining the value of salvage vehicle components is foundational to the salvage business.

Triaging the battery upfront also eliminates unnecessarily moving it around. Shipping around heavy battery packs is expensive and complicated as they are likely to be storing a ton of energy in them still. Identifying the ideal downstream outlet for a battery pack ensures it goes to the outlet most likely to derive the top value from it and minimize the number of times it needs to be shipped.

Multiple Downstream Channels

Based on what they have seen so far, Smartville estimates that approximately 70% of the battery packs in salvage yards are in good enough condition to be put back into use as spares and replacement packs for EVs. That’s encouraging, as reusing the packs in other electric vehicles puts the entire pack back into use with the least waste.

Smartville’s containerized energy storage solutions repurpose the entire automotive battery pack. Image courtesy: Smartville

Continuing down the line, they estimate that around 10% of second life EV packs are damaged or otherwise not viable as donors for either a used vehicle replacement or to be repurposed as stationary storage. These packs could be prone to thermal runaway and should be sent off for bottom-up recycling. Being damaged, they present the highest risk for causing fires and similar thermal issues.

The final 20% of the packs are where Smartville plays. These are the packs that Smartville is looking for and that they will ultimately procure as the feedstock for their second life battery energy storage systems.

Building a Smartville Battery System

With the ideal packs for their systems identified, it is time to integrate them into Smartville’s containerized energy storage solutions. Before putting them to use, they do a second round of analysis, diving deeper into the pack to be sure it is up to the task.

Smartville’s energy storage systems are similar to the containerized energy storage systems sold by the big names in the battery industry like CATL and BYD, with the noticeable difference that Smartville does not break down the battery packs into their constituent cells, but rather, repurposes the full automotive battery pack in their containers.

They build the packs into containerized units, ideally bundling similar chemistries for simplicity, though this is not required. Their solution is able to balance the pack voltage across different chemistries, and because they’re really only working with the output of the automotive pack with all of its physical integrity, thermal management, and BMS intact, the process is simplified.

That’s right, they’re shoving full automotive battery packs into their containers, and this is part two of Smartville’s secret sauce. You see, they’re not simply using the battery cells from the pack. Rather, Smartville jacks into the packs via the communications system and puts them into a simulation a la The Matrix.

This approach maintains the integrity of the pack and all of its systems, which maximizes the durability and longevity of the pack. After all, if it was designed and built to stand up to use in a car, running inside a stationary container designed to support batteries should be a walk in the park.

Scaling from a single automotive pack up to what could qualify as a containerized battery energy storage solution is where things get really interesting. Smartville’s team of engineers manipulate the automotive packs with software via their native communications channels to make them think they are actually driving along the road to get them to produce the output needed.

Running the containerized packs in a simulation allows Smartville to adjust the power being put out from each pack in the array to get what they need from the system. From there, the power flows into specially designed power electronics which step the voltage up from whatever the automotive pack voltage is, whether at 400 or 800 volts, up to a typical output voltage of a battery energy storage system of around 1,600 volts.

Smartville is still in the early days of its startup journey, but what it has accomplished in the first four years is impressive. The company is far beyond simply having a vision and has already built several monetizable products to bring its vision into reality.

To learn more about Smartville, head over to the website.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

EV Obsession Daily!

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it!! So, we’ve decided to completely nix paywalls here at CleanTechnica. But…

Thank you!

Community Solar Benefits & Growth

CleanTechnica uses affiliate links. See our policy here.