Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Thomas Built Buses, a division of Daimler Trucks, is a leading manufacturer of school buses in North America. It introduced Jouley, its first battery-electric school bus, in 2017, and has delivered more than 1000 of them to school districts all across America. Because school buses follow predictable routes and have plenty of time to charge each day, they are the perfect EV. Powering school buses with electricity costs less than using diesel, propane, gasoline, or compressed natural gas. In fact, operating an electric school bus can cost less than half of what it would take to run an older diesel school bus.

For decades, school buses have been powered by diesel engines. Is there anything that makes less sense than loading children inside a diesel-powered metal box twice a day to get them to and from school? Young lungs are especially vulnerable to diesel emissions — especially particulates. We get all fired up about the Volkswagen diesel cheating scandal, but never stop to think about what comes out of the tailpipes of all those yellow school buses that crisscross the American landscape every day. Are we under the illusion that commercial diesel engines run cleaner than the ones used in passenger cars? We better not be. In fact, because they do not have to meet passenger car standards, chance are they are a lot worse.

If any part of the transportation sector deserves to be electrified, it is the school bus. Electric school buses provide a smoother, quieter ride than fossil fuel-powered buses. Not only does that mean a better driving and riding experience, it also creates a safe environment in which students are quieter and drivers are more aware of what’s happening inside and outside the bus.

Things have moved on from 2017, when the first electric Thomas Built Buses were manufactured. Since then, the company has partnered with two other companies to improve its products. One of those partners is Proterra, which manufactures the 246 kWh batteries for the buses. The company used to build innovative carbon fiber buses for transportation fleets. That business failed, but it still makes batteries for commercial customers that weigh less than the batteries from other suppliers. With its 800 volt architecture, it also permits Level 3 DC fast charging. Another partner is Accelera by Cummins, the electric drivetrain division of Cummins, which has been known for decades as a Tier One supplier of diesel engines. Detroit Diesel has also created an electric powertrain division as well.

Second Generation Electric School Bus From Thomas Built

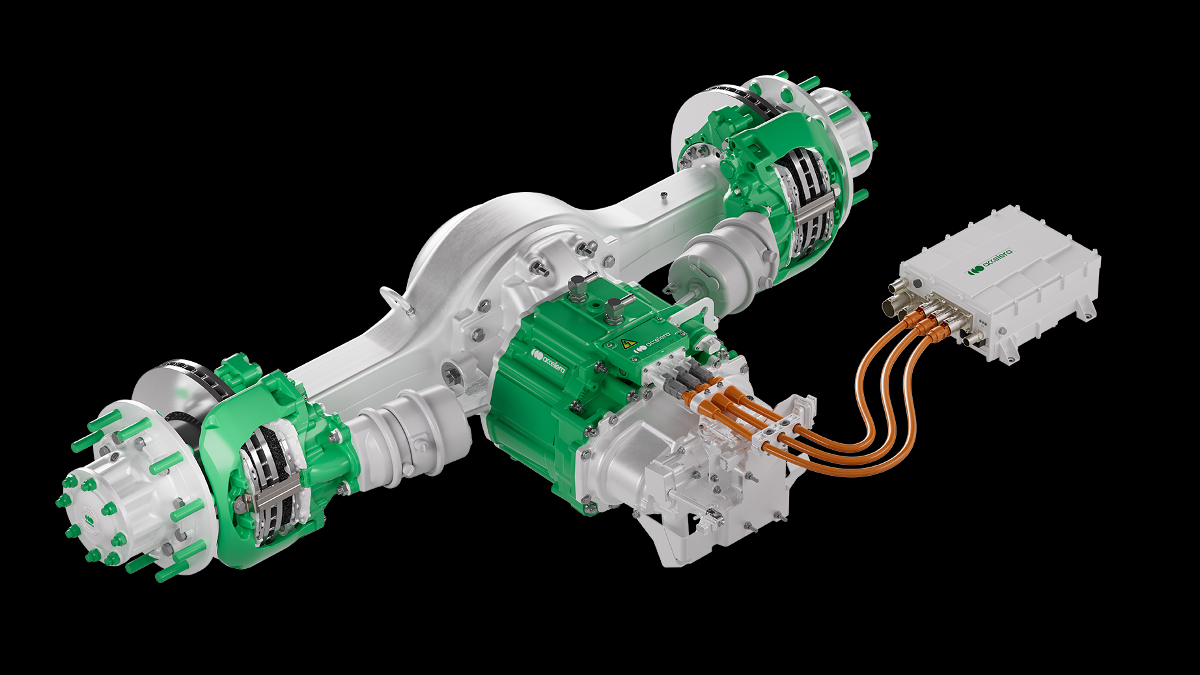

This week, Thomas Built Buses announced the launch of the second generation Saf-T-Liner C2 Jouley battery electric school bus. This second generation electric school bus incorporates customer driven improvements and technological advancements to create a product that excels in efficiency, performance, and serviceability. At the core of the second generation Jouley is the 14Xe eAxle from Accelera by Cummins.

This next generation traction technology is backed by 25 years and one billion miles of real-world transportation experience. A compact, all-in-one power source, the 14Xe eAxle integrates the motor, two-speed transmission, disc brakes, and rear-drive gear set into one package mounted on the rear axle. It removes the need for a traditional driveshaft, making the drivetrain lighter, more efficient, and reduced complexity. This design, coupled with Accelera’s ELFA inverter, delivers power directly to the wheels, enhancing acceleration and torque for a smoother ride.

The 800 volt Proterra battery system improves startability, gradeability, and acceleration. The higher voltage along with the eAxle makes it ideal for diverse terrains, including hills and mountains. This upgrade also supports the integration of additional components like air conditioning, heaters, and other essential features without compromising performance. The streamlined design of the eAxle simplifies maintenance by reducing the number of moving parts and centralizing major components, which leads to lower service costs and improved uptime for school districts.

The second generation Jouley electric school bus also features a new 12- by 12-inch toe board floor access panel that allows direct access to high-voltage junction box connectors without removing the battery packs. Additionally, the body heating loop surge tank has been relocated to the left side of the bus, providing even easier access and further simplifying maintenance tasks. These enhancements are designed to streamline diagnostics and repairs, enabling technicians to work more efficiently and get buses back on the road even faster and represent improvements suggested by the company’s experience with actual customers over the years.

A Longer Wheelbase For More Seating

The new Jouley architecture uses a 219-inch wheelbase, a feature requested by customers that allows seating for up to 60 passengers. Accelera’s eAxle enables shorter wheelbase architectures, significantly improving the overall maneuverability of the vehicle and making the bus ideal for navigating tight spaces and fitting into service bays.

The new liquid-crystal display (LCD) digital dash aligns with current automotive technology, offering drivers a more advanced and intuitive interface. The LCD dash supports a wider range of visual information, including crucial diagnostics and operational data. The integration of more detailed information and animations compared to previous instrumentation makes it easier to operate the bus safely and efficiently. Future updates can be implemented through software alone, enabling Thomas Built to provide ongoing technological enhancements without hardware changes.

“We are proud to introduce the second generation of our Saf-T-Liner C2 Jouley, a product that reflects our commitment to innovation, meeting the evolving needs of our customers and driving the future of sustainable student transportation,” said T.J. Reed, president and CEO of Thomas Built Buses. “With features that enhance efficiency, performance and serviceability, the new Jouley delivers unmatched value for both current electric bus operators and new adopters who are ready to embrace cleaner, smarter solutions.”

“Partnering with Thomas Built Buses to deliver the next-generation eAxle technology for the Jouley is an exciting step to decarbonize commercial transportation,” said Brian Wilson, general manager of eMobility for Accelera. “The 14Xe eAxle elevates expectations for performance, efficiency and serviceability, setting a new standard for the industry. School buses are an ideal application for electrification, and we are excited about the positive impact this innovation will have on communities and the environment.”

Production of the second generation Jouley in the 219-inch wheelbase has already begun. Additional wheelbase options will be coming in 2025. As the electric school bus authority, Thomas Built Buses continues to expand and optimize its lineup and service offerings, including infrastructure consulting. With its high voltage architecture, it is also a perfect candidate for vehicle-to-grid systems, which can serve as a source of income for school districts and transportation operators.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy