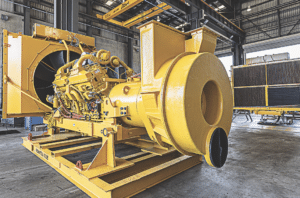

Rapidly growing mining services firm National Group made a major investment in its fleet to support clients.

A successful collaboration between National Group, Komatsu Australia and Cummins South Pacific is delivering efficiency gains and environmental benefits for mining companies through advanced engine technology.

In early 2023, National Group, a leading privately-owned mining services firm, embarked on the largest engine upgrade in its history.

The goal: upgrading each engine in 16 Komatsu 830E haul trucks used at the Lake Lindsay and Curragh coal mines in the Bowen Basin in central Queensland.

National Group’s multi-million-dollar project involved converting the Cummins Tier 1 QSK60 engines in the haul trucks to its ‘Advantage’ solution.

Cummins’ Advantage solution enables the QSK60 to be upgraded to the latest diesel technology at overhaul time with no major changes to the base 60-litre V16 design. The result is lower fuel consumption and greenhouse gas emissions, and a substantial extension to engine life in the haul trucks.

Image: National Group

National Group founder and managing director Mark Ackroyd said the engine project is part of the company’s ongoing commitment to providing one of the largest and most advanced equipment fleets in the Australian mining sector.

“National Group continues to invest heavily in its fleet,” Ackroyd said. “We are providing more equipment that utilises the latest technology to help our mining clients reduce their fuel consumption and carbon footprint.”

The engine upgrade is an important part of National Group’s broader environmental, social and governance, or ESG, strategy. In 2023, National Group launched a sustainability strategy to build on its previous sustainability achievements and provide a roadmap to expand its ESG focus this decade.

“The engine upgrade is the largest initiative so far resulting from National Group’s new sustainability strategy,” Ackroyd said.

“We plan to further expand our ESG focus and are encouraged by the early success of the engine upgrade project. The feedback from project stakeholders has been very positive.”

To date, 12 of 16 engines have been upgraded on time and on budget, with no safety incidents or project setbacks. The remaining engines are expected to be upgraded this year, meaning all 16 trucks will soon be out in the field.

Technical excellence

The project’s complexity is reflected in the amount of planning required, the number of people involved across three firms, and the scale of National Group’s investment to upgrade 16 engines.

Each engine, about 2.5m high and 3m wide, was removed on-site by Cummins engineers, then upgraded and resupplied as certified modular common-rail system, or MCRS, engines.

For National Group, that meant getting back the engines it originally purchased and are familiar to its on-site maintenance teams.

The modularised engines were then sent to one of Komatsu’s Mackay workshops for engine overhaul and upgrades, then returned to site to be reinstalled into the next 830E.

Each overhaul and upgrade in Mackay took around 200 hours, including extensive testing.

The key technology upgrade was to the engine’s fuel injection system. The early high-pressure unit injection system, or HPI, was replaced with the high-pressure MCRS that now feature on all of Cummins’ latest-generation high-horsepower engines.

Cummins’ Advantage solution also includes innovative combustion technology engineered for Tier 4 Final and Stage V emissions compliance – the most stringent off-highway emissions standards in the world, delivering a proven 63 per cent reduction in diesel particulate matter.

In addition, lower fuel consumption supports a reduction of Scope 1 carbon emissions aligned to the National Greenhouse and Energy Reporting, or NGER, scheme.

Cummins’ Emerald branch manager Glen Evans said the engine upgrade required extensive collaboration.

“A lot of credit should go to the teams at National Group, Komatsu and Cummins on this project,” he said.

“Everyone worked together really well to understand each other’s needs, what was required and how to ensure the project achieved its goals. The project has been a good opportunity for Cummins to expand its relationship with National Group.”

At the ground level, Evans’ colleague and Cummins product support representative Fredy Cerdan liaised with National Group maintenance superintendent Damien Melville.

A larger group of stakeholders from National Group, Cummins and Komatsu was then formed and the group met before the project officially began.

Delivering results

Komatsu Australia’s Queensland regional service manager Gary Clarke said a unique feature of the Komatsu 830E truck is its modularisation.

“All the engine components are in one module that slides in and out of the 830E,” he said. “It’s a really great design and means we were able to complete all of the upgrades and modifications off the truck which reduced downtime when we completed the installations on-site.

As Clarke explained, the task is made more sophisticated by the size of the engines.

“With the MCRS engine, we are installing a 60-litre engine into a very large haul truck,” he said. “For comparison, with a car, you’re typically talking about a 3-4-litre engine.

“But there have been no quality issues with the build or installation, everything has been delivered on time and there have been no safety incidents.

“The first upgraded 830E has been in operation for over a year and 11 others are in the field. From Komatsu’s perspective, the results so far have been as expected.”

Clarke said Komatsu welcomed the opportunity to work closer with National Group.

“It’s one of the biggest projects Komatsu has ever undertaken for National Group, so it’s great that the relationship between our organisations continues to grow,” Clarke said. “The National Group and Cummins teams have been great to work with.”

Equipment upgrades to achieve improved environmental outcomes are not mandatory, making National Group’s investment all the more impressive.

“Costly upgrades of equipment to deliver these benefits are not something mining contractors in Queensland are required to do,” Clarke said.

“The direct benefits of reduced fuel consumption and lower greenhouse gas emissions go to the client rather than the contractor.

“But National Group had the foresight to make a major long-term investment in this project for its clients, even though it receives indirect benefits from the engine upgrade.”

For Ackroyd, the main benefit is helping National Group clients achieve their goals.

“Our firm’s DNA has always been built on being customer-focused,” he said. “Our clients want to use mining equipment that reduces their carbon footprint through lower fuel consumption.

“We are responding to our clients’ needs through this investment in engine upgrades.”

Image: National Group

Ackroyd said the project also delivers other long-term benefits.

“We’ve further strengthened our relationship with Komatsu and Cummins and our people have learnt more about collaboration on large projects,” he said.

“As we continue to expand and upgrade National Group’s fleet, in response to rising demand for our services, the ability to collaborate with other firms is increasingly valuable.”

Another benefit of the project is its alignment with National Group’s sustainability strategy.

“The risk with developing a sustainability strategy is that it looks great on paper, but ultimately sits on the shelf,” Ackroyd said.

“This project shows how serious we are about implementing our new sustainability strategy and expanding our ESG focus through major investments that will benefit our clients, mining workers, communities and the environment for years to come.”

And when it comes to further expansion, Ackroyd said he expects National Group to further upgrade its fleet in the next few years.

“It’s something we are looking at,” he said. “Our business has a lot of momentum and capacity to invest.

“We see the quality of our fleet, and the maintenance skills behind it, as key competitive advantages that we continue to build on to support our clients as they grow.”

This feature appeared in the December 2024 issue of Australian Mining.