If you’ve been in the metal procurement game long enough, you’ve likely encountered unanticipated market shocks. These rare occurrences, known as “Black Swan events,” hit hard, leaving devastating consequences in their wake. From global pandemics to geopolitical conflicts, Black Swan events can cripple industrial metal markets, forcing companies to scramble to source critical materials and protect their bottom line. MetalMiner’s weekly newsletter offers many tips and tricks to help you navigate Black Swan events.

What is a Black Swan Event?

A Black Swan event refers to any unforeseen incident with significant ramifications. In the world of industrial metals, such occurrences often strike suddenly, making it nearly impossible for businesses to plan ahead. The COVID-19 pandemic serves as a prime example. The pandemic caused severe price volatility for metals like steel and aluminum, abrupt demand shocks and supply chain disruptions. Companies that relied on stable supply chains faced higher costs or, in some cases, endured lengthy delays that brought production to a complete halt.

Another example is the 2008 financial crisis, which caused demand to collapse across industries and sent metal prices plummeting. Businesses that hadn’t prepared for such a downturn saw themselves left with expensive inventory and virtually no demand.

How Black Swan Events Impact Metal Sourcing Companies

A Black Swan event can shake metal sourcing companies like an earthquake. For instance, oil prices briefly declined during the pandemic, while metal prices like copper and steel fluctuated wildly. In turn, those businesses that choose not to sign long-term contracts ended up paying much more for their purchases.

Furthermore, geopolitical unrest or natural calamities can halt the production and transportation of metals. The 2011 Fukushima disaster, which struck Japan after a massive earthquake and tsunami, significantly impacted the world’s nuclear industry, caused factory closures and created transportation problems that disrupted the steel and copper markets. Unfortunately, when these disruptions happen, it’s often too late to find substitute providers without paying more. (Read more about how to smooth out volatility from such events in the 5 Biggest Cost Saving Sourcing Tactics).

Black Swan events frequently trigger traffic jams and other logistical issues. Lead times become erratic due to factors like port closures, labor shortages or political penalties, making it challenging to stick to production schedules.

How Companies Can Mitigate the Impact of Black Swan Events

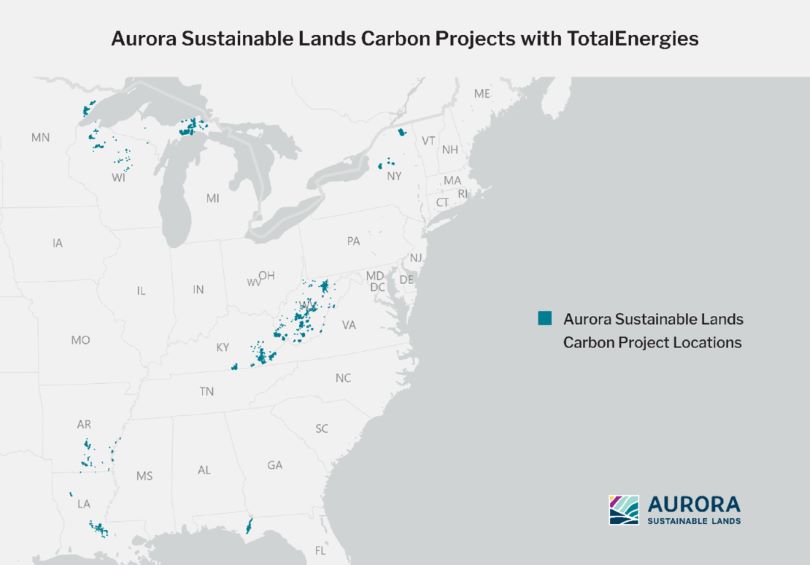

Black Swan events help to illustrate how relying on a single source or region can carry significant risk. By diversifying your supplier base across multiple regions, you ensure you have alternatives if political upheaval or supply chain disruptions occur in a given country or area of the world.

Furthermore, locking in metal prices through long-term contracts can help protect against price volatility (read more in the free resource, Metal Price Contracting Indexes: The Secret Procurement Profit Tool). For example, businesses with fixed contracts were able to keep their costs more stable, reducing exposure to short-term price spikes, even when the spot market surged during a Black Swan event.

Access to real-time data is one of the most important tools in managing metal sourcing during volatile times. Platforms like MetalMiner Insights provide companies with the intelligence they need to anticipate and respond to rapid market changes. Whether it’s forecasting metal price movements or spotting supply chain risks early, data-driven decision-making can help you act fast.

Other Valuable Volatility Management Techniques

Regularly monitoring market trends and forecasting resources is one of the best ways to spot potential risks. For example, businesses that could recognize the early warning signs of a slowing Chinese economy were better prepared to manage recent drops in steel and aluminum prices caused by declining demand. Staying informed allows you to make proactive adjustments to your sourcing strategy.

A reliable supply chain visibility system gives you real-time insights into your supply routes, enabling you to respond quickly to disruptions. With advanced visibility tools, you can swiftly switch to alternative suppliers if a key one becomes unavailable, without disrupting your production schedule.

In today’s global economy, Black Swan events are a matter of “when,” not “if.” The companies that thrive are those that prepare in advance, building flexible, data-driven sourcing strategies that can withstand even the most unpredictable challenges.