Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

24M is one of the many companies formed to commercialize ideas from the fertile brain of Yet-Ming Chiang, an MIT professor who has sparked innovations like Sublime Systems, which uses electricity to create low carbon cement at room temperature. The common factor in all his endeavors is taking disruptive technology and making it commercially feasible.

The company says, “24M answers the world’s need for affordable energy storage by offering a revolutionary battery manufacturing and product design technology set enabled by the 24M SemiSolidTM and Unit Cell manufacturing platform. By re-inventing today’s battery products and manufacturing methods, 24M solves the critical, decades old challenge associated with the world’s preferred energy storage products and technologies — reducing their high cost while improving their performance, safety and recyclability.”

Back in 2015, Tina Casey first brought news about 24M and its so-called semi-solid-state batteries to the attention of CleanTechnica readers. Five years ago, 24M shipped its first batteries to commercial customers. In a press release at the time, the company said, “These deliveries represent a significant milestone in the 24M mission to scale its unique, capital-efficient, low-cost approach to advanced lithium-ion battery manufacturing.”

Then late last year, 24M announced it had designed a radical new way of manufacturing its batteries that it called electrode to pack, “The 24M Electrode To Pack (ETOP) system is a streamlined battery pack system that features electrodes packaged directly into the battery pack, removing the need for individual cells and modules,” the company said.

“24M ETOP™ will be a game-changer for electric mobility and energy storage systems because it delivers unmatched energy density,” said Naoki Ota, 24M President and CEO. “This innovative new battery technology is enabled by our Unit Cell technology and is reflective of what’s yet to come from 24M. We are moving beyond our core technology — the 24M SemiSolid™ manufacturing platform — into a company with a revolutionary technology set that will deliver truly transformative solutions for a better energy future. 24M ETOP™ will be a game changer for electric mobility and energy storage systems because it delivers unmatched energy density.”

24M Says New Battery Will Have 1000 Mile Range

Fast forward to February 12, 2024, when the company announced its latest addition to its disruptive battery technology portfolio — Eternalyte™, a transformative new electrolyte developed specifically for lithium-metal batteries. The proprietary, liquid electrolyte formula will enable significant improvements in the cycle life and rate capability of lithium-metal batteries for electric vehicle, energy storage and consumer applications, the company says.

This new innovation builds on the recent technology breakthroughs from 24M including 24M ETOP™, its electrode-to-pack battery technology, and 24M Impervio™ its new battery separator. When combined with Eternalyte™ the three new technologies go beyond 24M’s SemiSolid™ and Unit Cell manufacturing platforms and offer a battery technology suite that enables a sustainable energy future.

Until now, solid-state electrolyte technology has been the preferred choice for those trying to commercialize lithium-metal batteries, which have long offered the promise of dramatically higher energy densities. However, safety concerns and short and inconsistent cycle life, caused by lithium or other metal dendrites, continue to limit the commercial viability of lithium-metal cells, including those using SSE-based technologies. Challenges with SSE’s scalability, cost, fragility, and changes in electrical resistance with cycling are additional issues that need to be solved.

24M’s unique liquid electrolyte, Eternalyte™, combined with Impervio™ solves these challenges. The combination is a low cost way to prevent all metal dendrites and achieve excellent cycle life with consistent and low electrical resistance to cathode active materials. Historically, liquid electrolytes used with lithium-metal anodes had poor cycle life, particularly, with rapid charging. Eternalyte™, however, has demonstrated outstanding cycle life even under rapid charging conditions, paving the way for new lithium-metal solutions.

“We are on a mission to deliver transformative battery solutions that overcome critical industry challenges. Eternalyte™ plays a key role in making that transformation happen by enabling high cycle life lithium-metal batteries,” said Naoki Ota, 24M President and CEO. “While our solutions can be individually integrated into conventional battery products, we believe the most significant benefits are achieved when they are combined. Together, they can deliver a cost effective and safe 1,000 mile per charge battery pack — enabling electric vehicles to be fully competitive with combustion engine vehicles.”

Promising Test Results

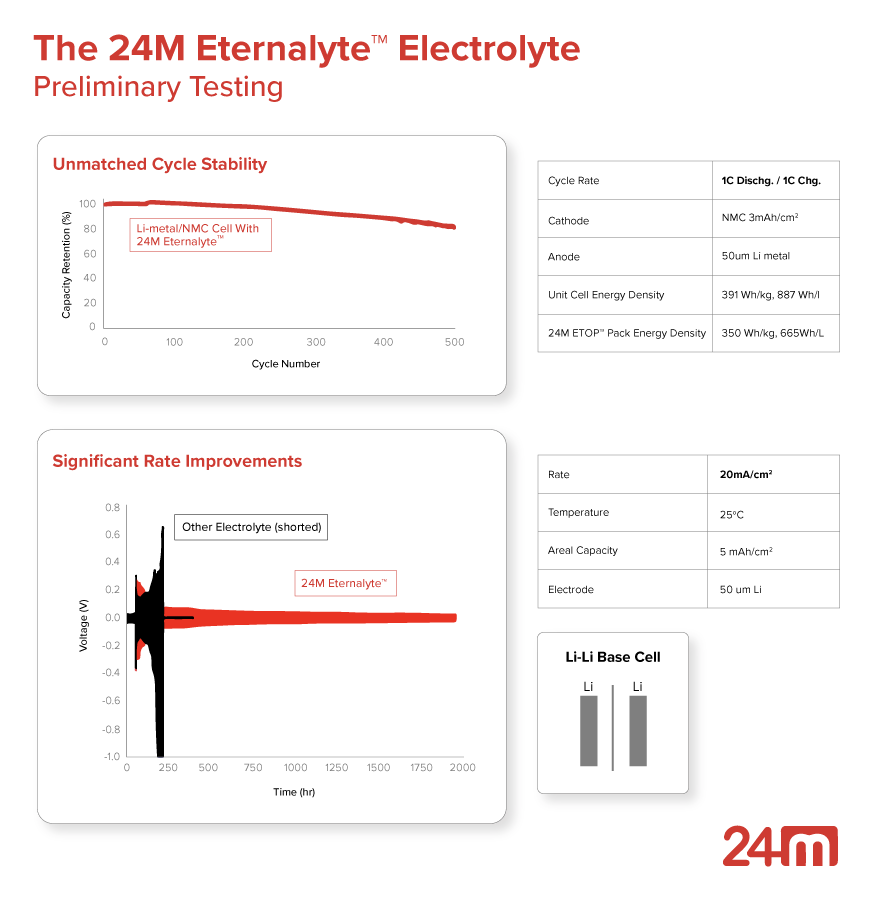

Early test results show that Eternalyte™ enables substantial improvements in cycle life and rate capability for lithium-metal batteries with unmatched cycle stability. For a lithium-metal cell cycling at 1C discharge/1C charge, 24M Eternalyte™ allows the cell to retain 83% capacity over 500+ cycles, which is equivalent to more than 500,000 miles of total range. The new battery technology is expected to allow up to 1,000 miles of driving per charge.

Test results for lithium-metal base cells suggested an equivalent of 3,000+ cycles with 4C continuous cycling without shorting or increasing resistance. 24M believes that Eternalyte™ has achieved the highest cycle stability among liquid electrolyte systems under 20mA/cm2 plating/stripping current. Please see the graphic showing technical details below. It shows the new batteries have a unit cell density of 391 Wh/kg and 887 Wh/L. The figures at the pack level are 350 Wh/kg and 665 Wh/L.

The Takeaway

It is a given around the sauna and ice bath area at CleanTechnica that the batteries which will power our vehicles in 2030 are in the laboratories of today. We have no idea who will win the race to make those next generation batteries, but if you said 24M, we wouldn’t be surprised. The company is loaded with world class talent from top to bottom. Cell to pack is the new new thing today, but electrode to pack is a more efficient way of making batteries by at least an order of magnitude.

What is exciting to those of us who advocate for the EV revolution — the transition to all battery-electric vehicles — is the prospect of batteries that can go a long, long way before they need to be recharged and can be recharged quickly when the need arises. The new battery technology from 24M seems to be just what the doctor ordered for the EV revolution to succeed.

Now the 24M batteries need to be field tested by automakers to verify their performance, including cold and hot weather operation. What the company may have done with this announcement is raise the curtain on the next phase of electric vehicle adoption. Eliminating range anxiety would provide a huge boost to the world of electric cars and trucks. The future of electric transportation is getting closer all the time. In fact, thanks to 24M, it may already be here.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica TV Video

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it!! So, we’ve decided to completely nix paywalls here at CleanTechnica. But…

Thank you!

CleanTechnica uses affiliate links. See our policy here.